Laser marking for production lines

Is it possible to integrate a laser marking machine in a production line, in a chain production conveyor? The answer is yes, without a doubt. There are many companies that use marking , ink and labeling systems for their products on a daily basis. In recent years, laser marking has gained popularity among companies to implement quick engraving and marking on different materials, but an application that is sometimes unknown is the possibility of integrating this laser marking machine into a production line . We are going to get to know this possibility in detail, which can help us work more efficiently and with high quality.

Laser equipment for chain productivity

Fiber laser marking machines are equipment oriented to laser marking of different materials. With this type of laser equipment we avoid using glues and inks, and we can quickly obtain high quality and detailed permanent marks. The LC-FIBER PRO model is a state-of-the-art marking range designed for integration into production lines and chain productivity. The fiber laser is a type of high-quality laser, in this case it adds to the incredible performance of GALVO technology, which works with a system of small mirrors that move at high speed, driving the laser beam to a surface.

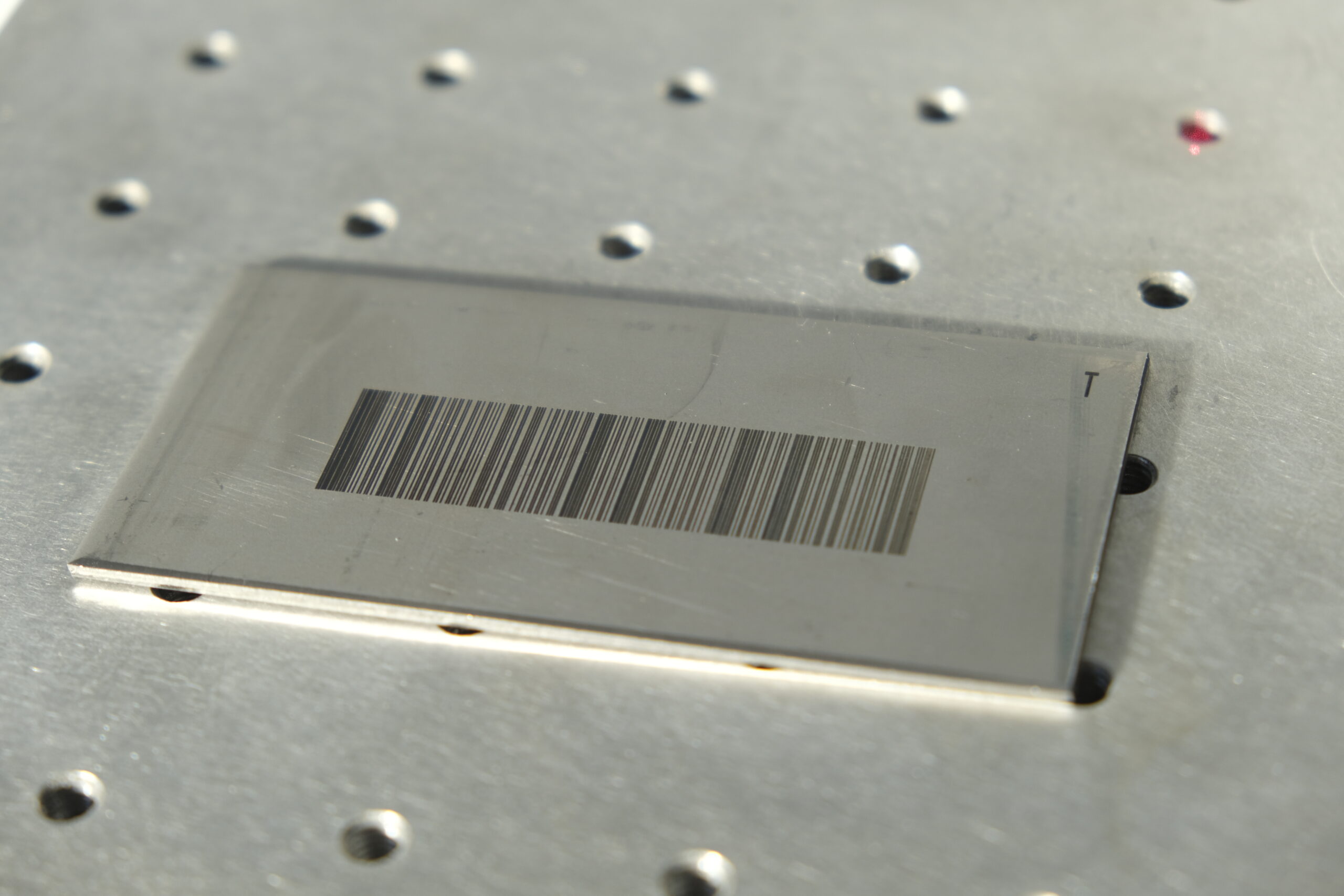

The LC-FIBER PRO range is an advanced model of the classic LC-FIBER ready to be integrated into a production line . It has a simple software configured to work with different possibilities, with an intelligent interface and automated processes with integrated control. It is a perfect system for any traceability with an easy management system, with possibilities of automation and integration into a system already in place. These laser equipment have different marking possibilities : lines, circles, triangles, codes, images and consecutive dynamic designs such as: dates and times, serial numbers, texts or barcodes.

These machines have different digital inputs and connections to facilitate their implementation in each industry and company.

What applications can we make?

As we have been detailing, laser marking machines for production lines can work with different materials, such as:

- Stainless steel

- Carbon steel

- Aluminum

- Copper

- Gold

- Silver

- acrylic painted

- PVC

- ABS and other plastics

These materials can be worked with great quality and definition of details , this laser equipment could be integrated into a production line for applications such as:

- Tool marking.

- Marking of expiration dates.

- Marking of barcodes and QR codes.

- Marking of serial numbers.

- Logo marking.

- Marking of relevant information on packaging.

With this and many more options, this equipment is interesting for sectors such as food, the automotive industry, machining, among other options. There are many types of applications that can be easily implemented with laser marking.