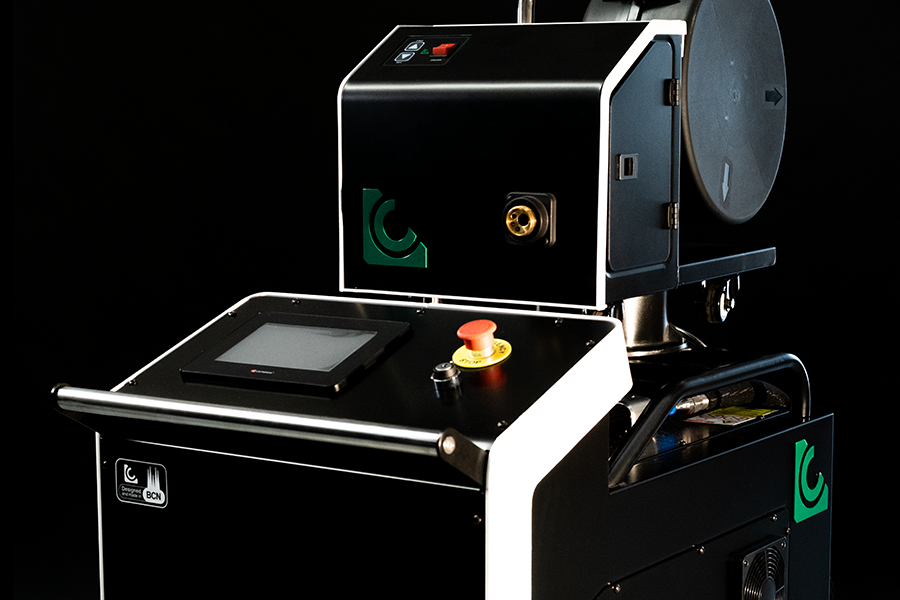

LC-WELD SMART Laser welding machine SMART

The SMART version of the laser welding range

LC-WELD SMART is the smallest version of our laser welding products with very simple and intuitive software. Part of the LC-WELD range, it is a simpler device but with the same quality as other laser welding equipment in the LC family.

The SMART version of laser welding equipments.

Parts and features of the laser welding machine smart

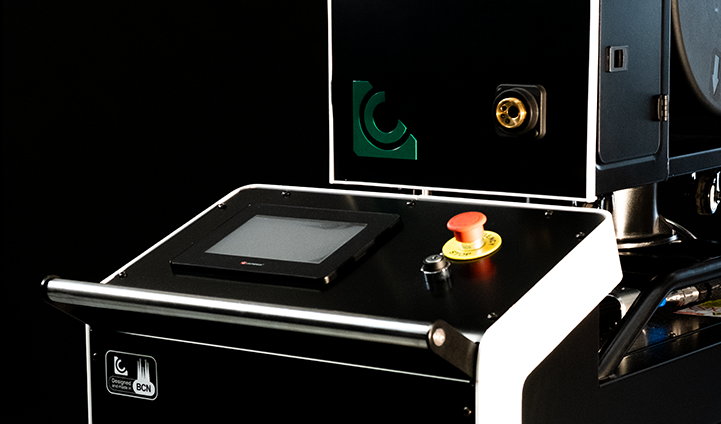

Removable feeder

Without the need to use an external system. Winder designed to work at low speeds. It has an electronic board manufactured and designed by LC.Touch screen

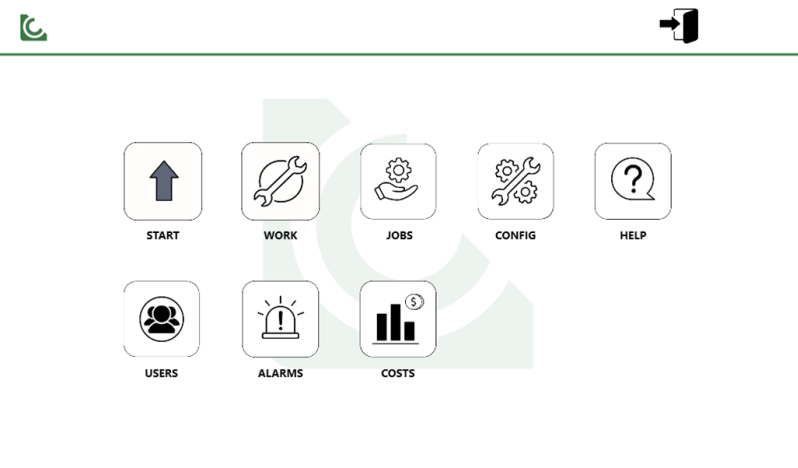

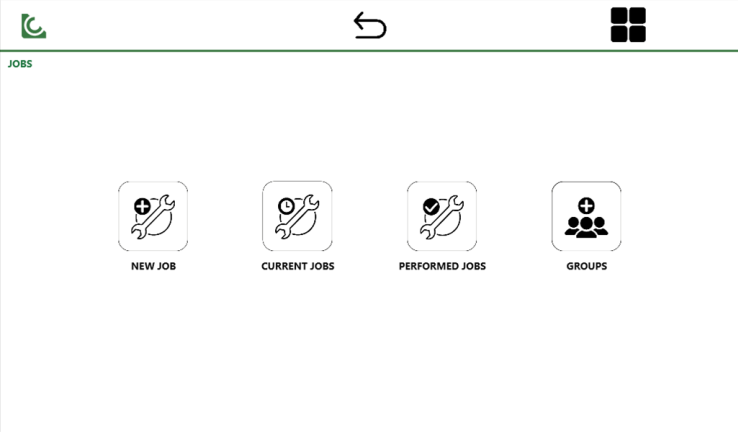

The screen of the LC-WELD Laser welding equipment allows simple and practical management of the machine's parameters, simplifying its options as much as possible without reducing its capabilities. It is organized into different windows within the screen: one for controlling the welding parameters, another for controlling the laser light beam, and another with technical details and the option to change the language.Ergonomic maneuverable laser gun

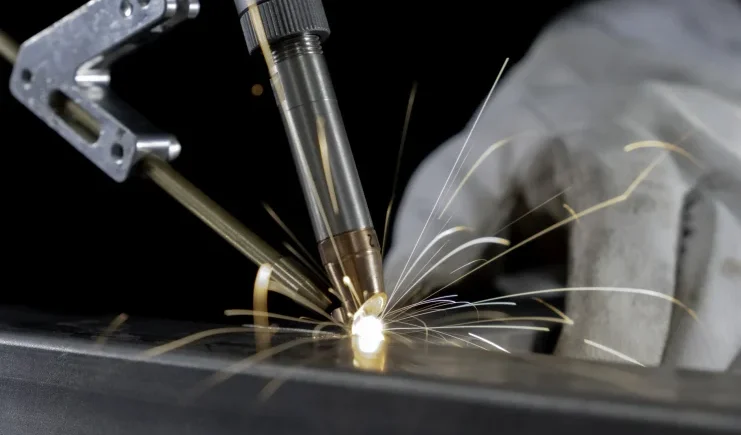

The gun or torch that incorporates the LC-WELD Laser welding equipment is the most advanced on the market, providing a variety of options unprecedented in the sector. Compared to other options, it is better in many aspects: the lens protector drawer, the uniformity in the measurement of the nozzles, the threaded fixation of the focal length, and a screen that shows us the parameters of the galvanometer motor make it This system is the most advanced in its category.Electronics by LC

Electronics designed specifically for this laser welding equipment developed by LC with its own firmware.Pneumatic wheels with brake

It makes it easier for us to move and transport laser welding equipment on flat terrain. It also has brakes that allow us to immobilize the machine, thus avoiding any type of accidents.Gun holder

Support to roll up the hose and safely and comfortably leave the laser welding gun.Interchangeable nozzles and laser cleaning

Equipment with the capacity to perform laser cleaning by exchanging the nozzle. In the same way, it is possible to vary the types of welding jobs by simply exchanging the nozzles.Advantages of laser welding machine smart

The LC WELD SMART manual laser welding equipment gives us the option of working with or without integrated wire input. It is an easy-to-use equipment that allows us to make very fine welds without losing strength or resistance.

Highly configurable equipment to perform different welding techniques and different materials with the same equipment. Very versatile equipment, we can weld different materials.

Removable winder without the need for a new external system. Improved drag quality with self-made electronic board and original design.

Equipment with a latest generation laser generator with an improved efficiency of 40%.

LC WELD SMART allows us to work different metals with the same machine. We can perform welding on carbon steel, stainless steel, aluminum, galvanized steel, titanium and special alloys.

The LC WELD SMART equipment is the smallest of the LC WELD laser welding range. A more maneuverable and lighter equipment, but with the same quality.

We use a continuous wave (CW) laser that gives better and higher quality results compared to other lasers such as quasi-continuous (QCW). Greater speed, less material deformation and more depth. Laser designed and prepared specifically for laser welding.

Gun with better duty factor for welding such as aluminum.

LC WELD SMART offers us the possibility of working on high-quality welds, very fine beads, complete penetration and without excess addition. We save time on polishing and expenses. With the laser, firm and deep welds are obtained without overheating the material, with much less deformation of the materials, especially those with low thickness.

The LC WELD SMART manual laser welding equipment gives us the option of working with or without integrated wire input. It is an easy-to-use equipment that allows us to make very fine welds without losing strength or resistance.

Highly configurable equipment to perform different welding techniques and different materials with the same equipment. Very versatile equipment, we can weld different materials.

| WELDING | |

|---|---|

| Stainless steel |  |

| Galvanised steel |  |

| Aluminum |  |

| Titanium |  |

| Carbon Steel |  |

Available downloads

For more information about laser solutions, download our online catalogues.

Contact

our sales

team now

We answer you in

less than 24 hours