Laser welding with Galvo technology

The Galvo welding machines allow automatic and semi-automatic welding with great precision and quality in one machine. This technology combines the basic fusion welding system with galvanometric technology, providing excellent control over the welding process.

Laser welding combined with galvo technology allows automatic and semi-automatic welding. Precision and quality in a single unit.

Parts and features of the galvo laser welding machine

High safety switch system

The laser welding equipment has a series of switches to turn on the machine and an alarm system for machine control. It is designed to be easy to install a semaphore with light warning and safety systems connected to an enclosed work area.Laser Chiller

The "Chiller" or refrigerator is used to cool the Laser resonator and the pistol or torch, to maintain a stable temperature in both, since the energy produced gives off remarkable amounts of heat. The chiller should always contain distilled water, and the level should not fall below the line between normal and full, periodically checking the level and changing the water every 4 months of continuous use.Practical and complete SOFTWARE

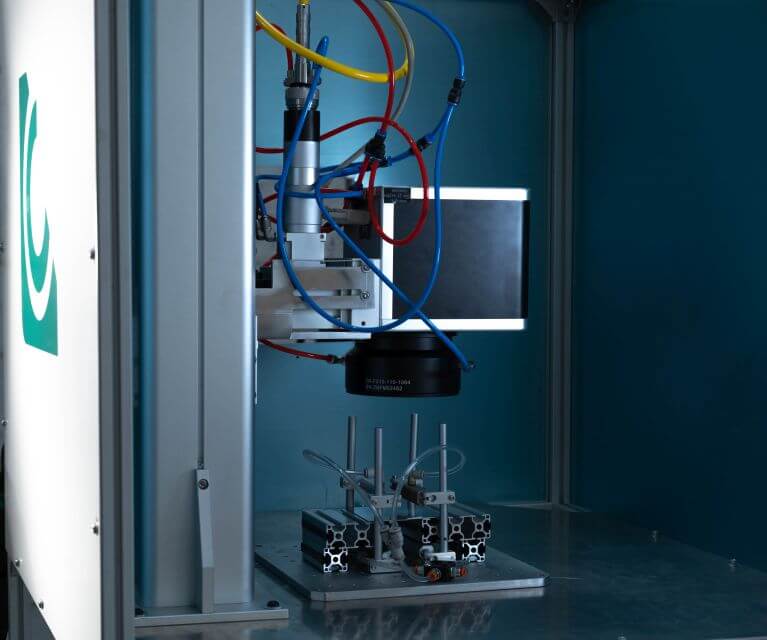

It allows easy communication with other devices and signals through digital inputs and outputs. Likewise, it has its own graphic editor or the possibility of importing external files with the desired welding designs in other formats.HD camera

The Galvo laser welding equipment has a built-in HD camera to view the welding being performed at all times from a distance. This allows us to see the welding process live.Laser resonator

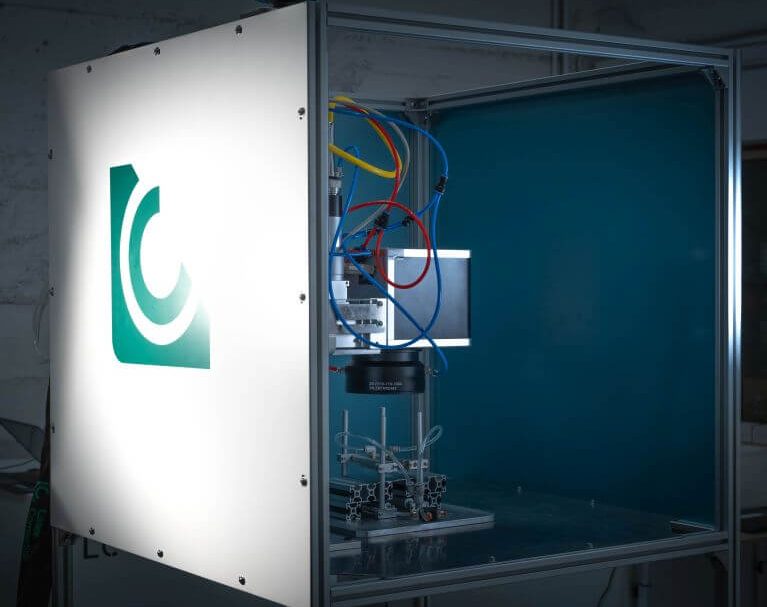

The laser resonator produces the laser beam, which is directed to the pistol by means of a flex with a fiber optic cable.Laser cabin

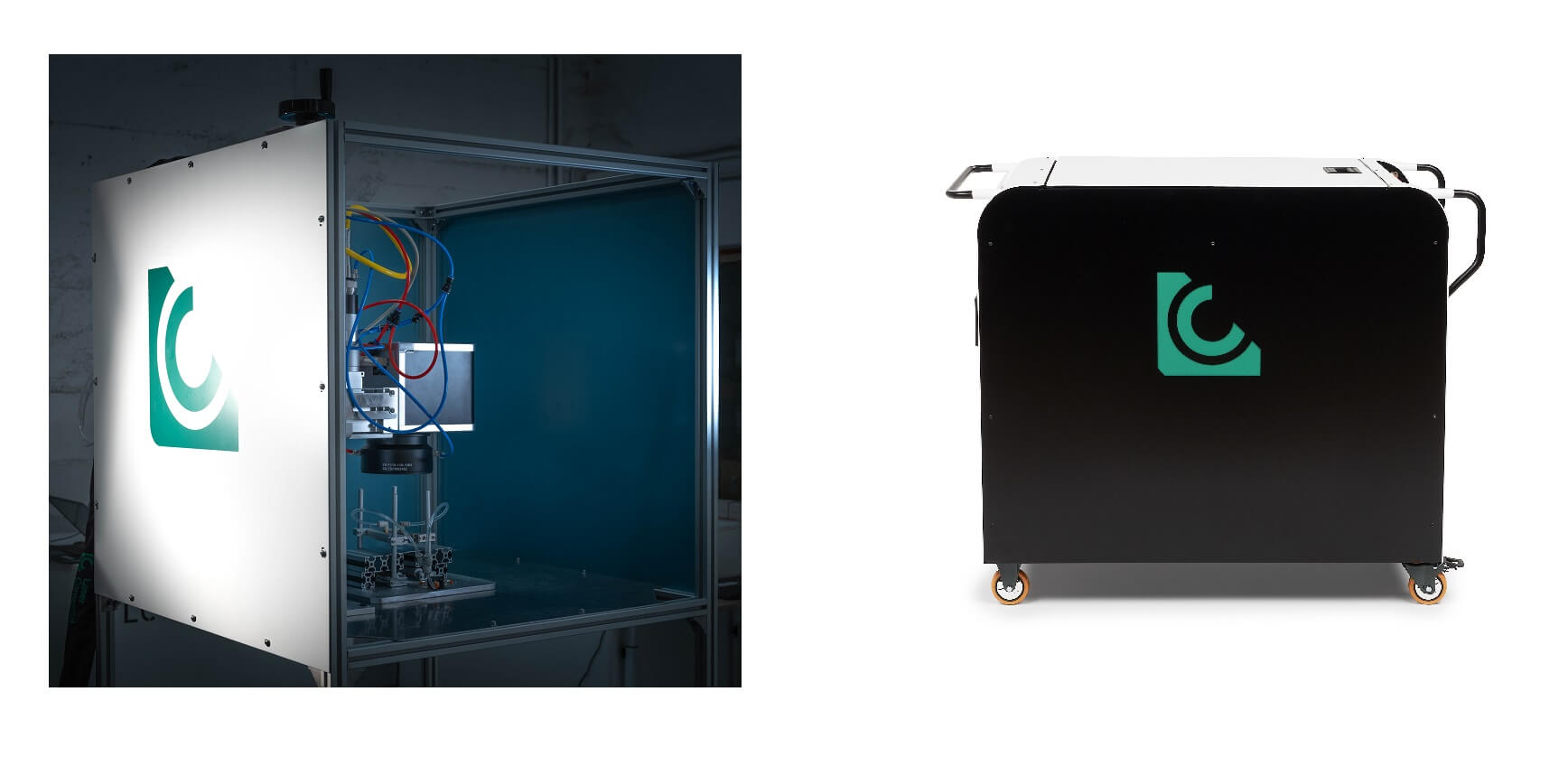

They are laser safety cabins composed of a system of panels, suitable to protect people in the environment where the laser welding process takes place.Fixed Galvanometer Head

The machine has a system of movable mirrors where the laser beam bounces, inside a closed head and passing through a lens that powers it, facing the surface. This technology allows that the head does not have to reach the places where to act, but it remains fixed.Advantages of galvo laser welding machine

The Galvo welding machine is an equipment powered with automatic and semiautomatic galvanometric systems that allows a higher welding speed than normal.

We use a continuous wave (CW) laser which gives better and higher quality results than other lasers such as quasi-continuous lasers (QCW). Higher speed, less material deformation and more depth with full penetration. The LC-WELD laser has a high efficiency for better results. For this reason, we can ensure very thin beads, with a great depth and penetration, practically without spatter and without excess filler, thus saving a lot of time in polishing, resulting in a firm and deep weld without overheating the material too much, thus, obtaining much less deformation of the materials, especially in those with little thickness.

For a faster and easier experience, the software allows us to save the parameters of our preference, so that we can access them more quickly. This gives us the possibility to have different specific parameters stored for welding a type of material that we work with on a regular basis, which translates into significant time savings. We can save as many parameters as we want for the different welding operations we carry out on a daily basis.

Our machines integrate a type of laser that is specially designed for welding. That is to say, of the variety of lasers that exist, LC knows which type of laser is best suited to the needs of our customers in the welding sector, so that we can guarantee the best quality in each job.

The software is easy and convenient to use. It does not require a high degree of specialisation on the part of the user. It also has a simple graphic editor or otherwise also allows you to import your files from other programs in different formats to weld according to the desired design.

In the past, traditional welding set limits on the precision of the welding process, whereas laser welding technology has the characteristics of minimal heat input, which can make the metal compound produced during welding more uniform and thinner, making it a better alternative when welding. This significantly reduces the possibility of cracks or damage to the material after welding.

Non-contact laser welding reduces the use of toxic components, as well as the generation of fumes, slag and hazardous waste. Laser welding machines can accurately monitor the temperature of welded joints in real time and prevent burns, reducing the possibility of incidents with the laser process or the integrity of the operators.

The Galvo laser welding machine allows us to enhance the basic laser welding system with Galvo technology. In this way we will be able to make resistant and detailed welds in a semi-automatic way.

| WELDING | |

|---|---|

| Stainless steel |  |

| Galvanized steel |  |

| Aluminum |  |

| Titanium |  |

| Carbon steel |  |

Contact

our sales

team now

We answer you in

less than 24 hours