LC WELD PRO: The true revolution in laser welding

LC WELD PRO is the enhanced version with cutting-edge technology within the LC laser welding equipment range.

The true revolution in laser welding.

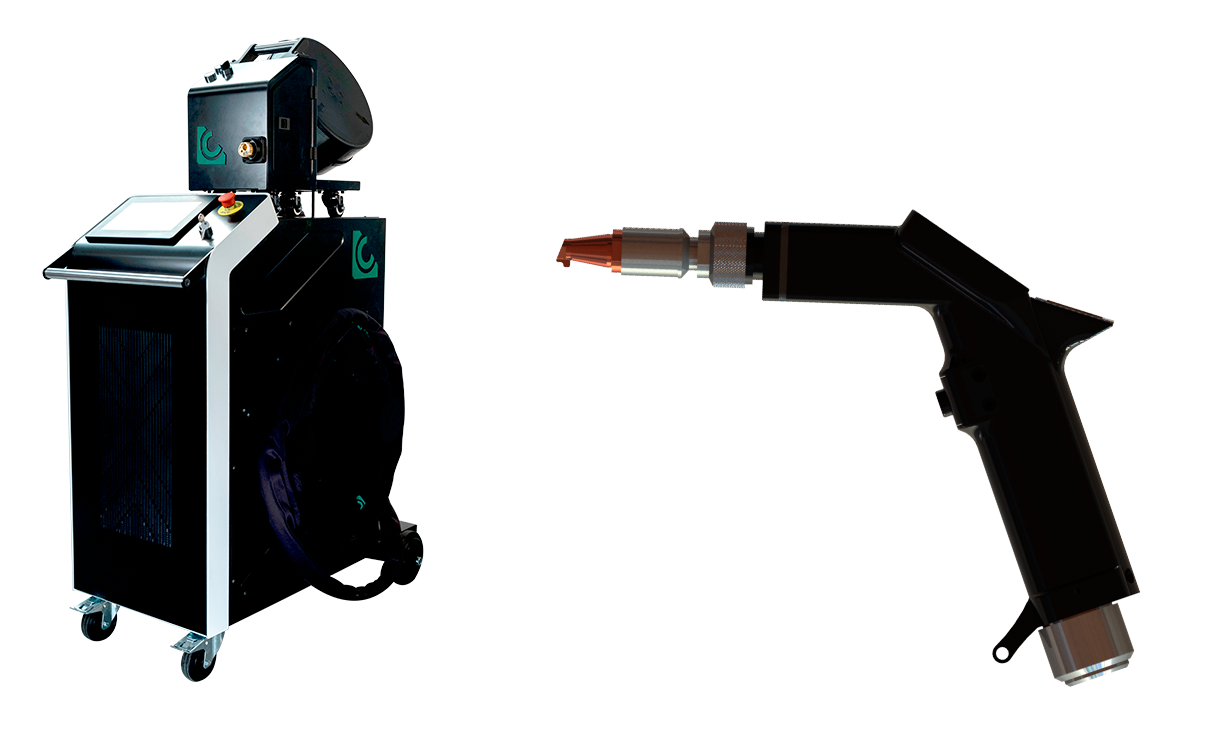

Parts and features of the laser welding machine pro

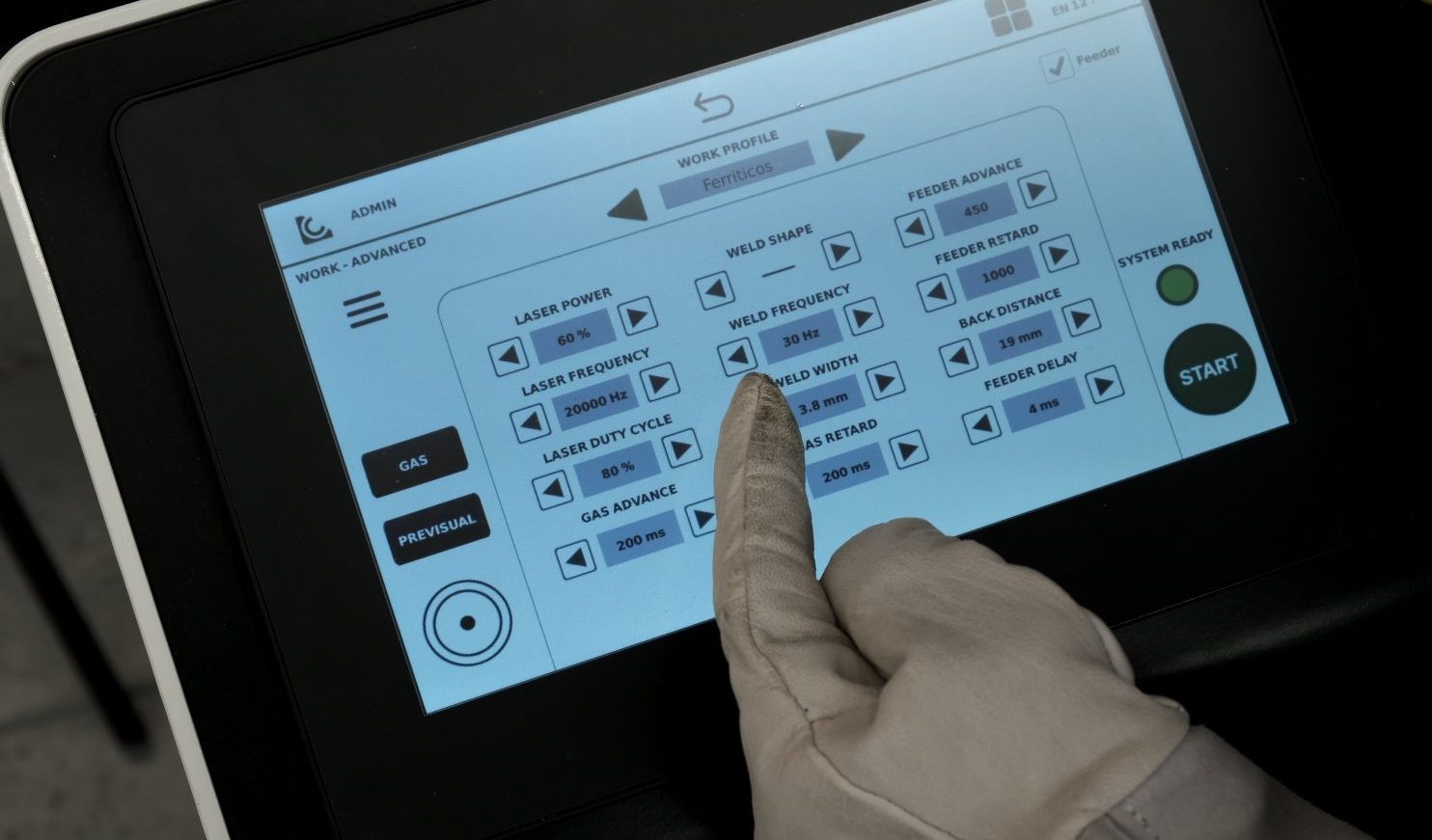

1. Touch screen:

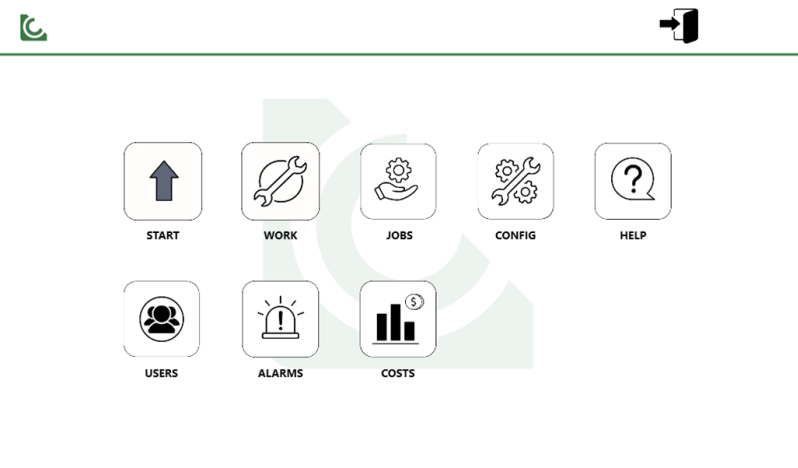

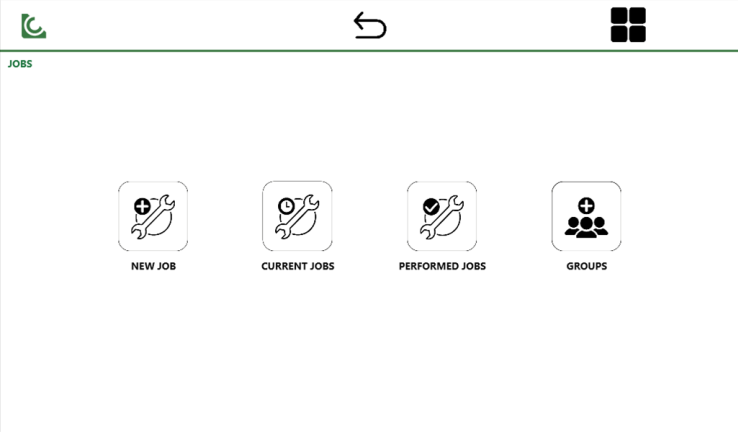

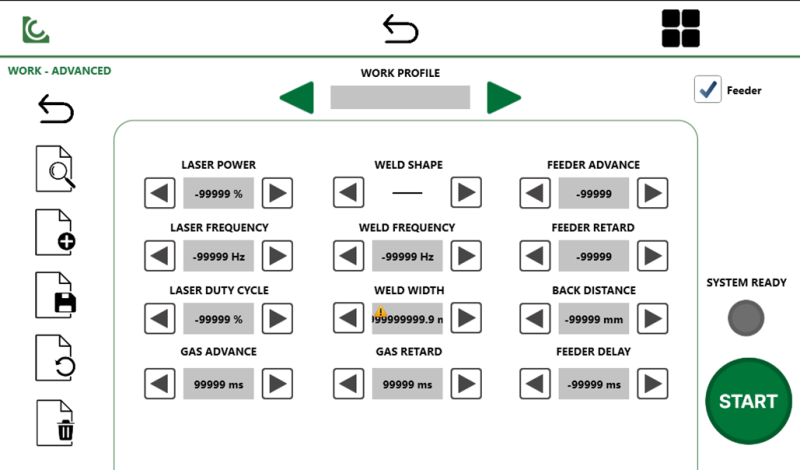

A single touch screen to control the wire feeder and laser equipment. Software specifically designed for laser welding with 4.0 technology, remote control, job programming and the ability to save parameters and jobs.2. Removable winder

Removable winder without the need of an external system. This winder is designed to work at low speeds, improving the performance of laser welding to obtain perfect results. It has an electronic board manufactured by LC.3. Encoder motor and improved drag quality

Encoder motor of European manufacture. Winding machine adapted to laser welding.4. Pneumatic wheels with brakes:

It facilitates the movement and transport of the laser welding equipment on flat terrain. It also has brakes that allow us to immobilize the machine.5. Laser quality

The laser resonator produces the laser beam, which is directed to the pistol by means of a flex with a fiber optic cable.6. In-house electronics

LC-designed electronics with proprietary firmware8. Improved running factor

Improved run factor for welding aluminum with material contribution efficiently and for a longer time.9. Interchangeable nozzles depending on the job

The nozzles are copper fixtures that are used as tools and positioners for different types of welding. There are different types of nozzles, which can also be classified if they are for welding with or without fiber wire contribution.10. Original LC design welding pistol

Galvanometric motors manufactured in the USA. Original LC design.11. Laser cleaning option

With a nozzle exchange it is possible to work with laser cleaning with the same equipment. With this option we can clean welds.Advantages of laser welding machine pro

Option of cleaning welds with the same laser equipment by exchanging the nozzle.

Our machines integrate a type of laser that is specially designed for welding. In the variety of lasers that exist, LC knows which type of laser is best suited to the needs of our customers in the welding sector, so that we can guarantee the best quality in each job.

Removable wire feeder without the need for a new external system. Improved wire feeding quality. Feeder designed to work at low speeds and improve the performance of laser welding. Feeder motor with encoder.

Electronics developed by LC with its own firmware.

Own software developed by LC with different functionalities for laser welding: cost control, variety of configuration, videos and documentation in the same equipment, user management, among other options.

Own design with improved ergonomics. Improved running factor in aluminium. Incorporates indicator light when the laser is in emission.

The manual laser welding equipment gives us the option of working with or without integrated wire input. It is easy to use and allows us to make very fine welds without losing strength or resistance.

This equipment is highly configurable to carry out different welding techniques and different materials with the same equipment. Very versatile equipment, we can weld different materials.

| WELDING | |

|---|---|

| Stainless steel |  |

| Galvanised steel |  |

| Aluminium |  |

| Titanium |  |

| Carbon steel |  |

Available downloads

For more information about laser solutions, download our online catalogues.

Contact

our sales

team now

We answer you in

less than 24 hours