This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Laser marking and engraving: Comparison between fiber lasers and CO2 lasers

Summary

If you are interested in the laser marking and engraving industry , you are probably know that we can find different types of laser machines: fiber lasers and co2 machines. But not everyone is aware of their differences, unique features, advantages and disadvantages.

Because of the versatility of laser machines , there are a huge number of ways to apply them. Everything will depend on different factors such as the use you want to give it, the applications you want to do with the laser machine, the system you want to apply or even the speed of the process. In LaserComercial we have the latest technology in laser machines , offering safe quality from the company and the best results.

For this reason, in this Blog we will go into all the details offered by each of these machines and we will help you choose which one is the most suitable. Let’s start by talking about some of their principles, properties, application industries, applied materials, and compare their differences.

Fiber Laser :

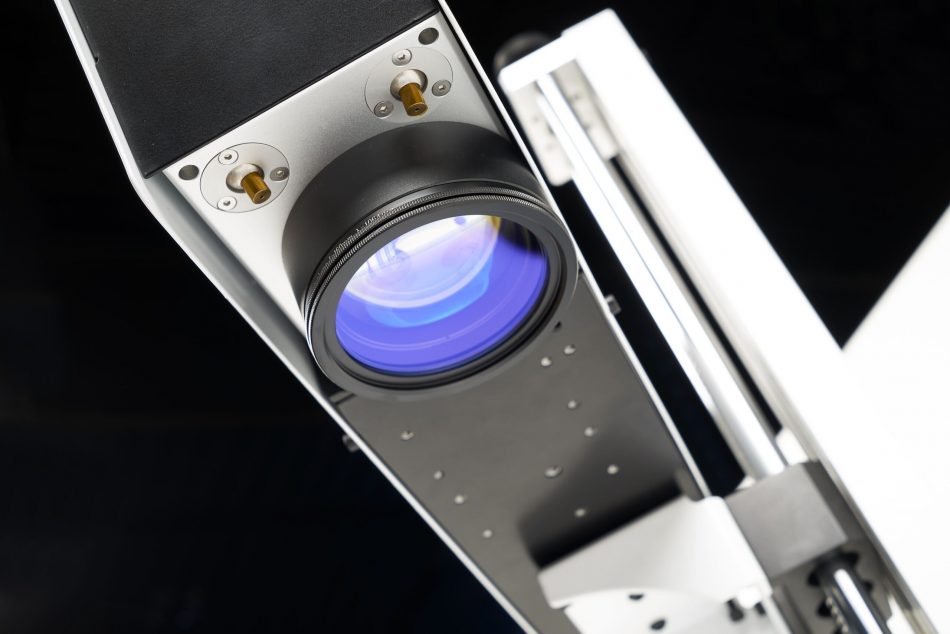

Now we will focus on fiber laser marking machines . Both co2 and fiber laser equipment have a Galvo head, a system of mirrors that conducts the laser precisely on a surface that we want to mark or engrave. In this system, two mirrors located at a greater distance from the material are used, which rotate quickly and reach the desired positions faster.

LaserComercial has some compact equipment designed to mark and engrave with laser. Dpending on the material and its thickness they could also cut. The fiber laser is suitable for marking materials such as: Stainless Steel, Carbon Steel, Aluminium, Copper, Painted Acrylic, Aerosol Glass, PVC… among other options.

Types of fiber laser markings:

The types of markings that we can execute with laser marking equipment will depend on the power of the machine. However, we can make different engravings and markings. The best known are:

- Annealing. It is used for metal marking. The oxidation process caused by laser is used to achieved a colored mark, instead of black. The resulting color may vary depending on the power used and the type of metal.

- Color marking. It is very similar to annealing. With this technique you can work different shades of color.

- Withdrawal of material . This technique consists of removing very little material from a surface so that a permanent engraving with the desired mark remains. The upper part of the substrate is engraved.

Advantages of fiber laser system

Laser marking equipment is very versatile and we could use it for very different purposes, they have a high quality fiber laser and a Galvo system. Next, we are going to list some reasons

that users who work with these fiber laser machines stand out the most:

- Through fiber laser marking we can mark different materials: stainless steel, aluminum, carbon steel, PVC, gold, copper, silver, glass spray, among others. Depending on the material, we can work with

clearer marks or deeper engravings. - permanent applications. The laser marking is permanent and cannot be easily changed, and these markings are of high quality.

- Reduction of environmental pollution . We avoid using glues and inks to mark and implement designs and codes. These products harm the health of the environment.

- Long useful life of up to 100,000 hours and an almost zero probability of failure. In addition, this laser is practically maintenance free.

- Easy operation. The laser marking equipment has a Plug and Play system and EzCad Laser Software that is easy to work with and learn to use.

- High speed. For some applications, the speed at which this equipment can reach is very interesting. It can reach a working speed of up to 8000 mm/s.

- Own production and design. LaserComercial marking machines are designed and produced in-house, every detail is carefully thought out so that it works from the first moment.

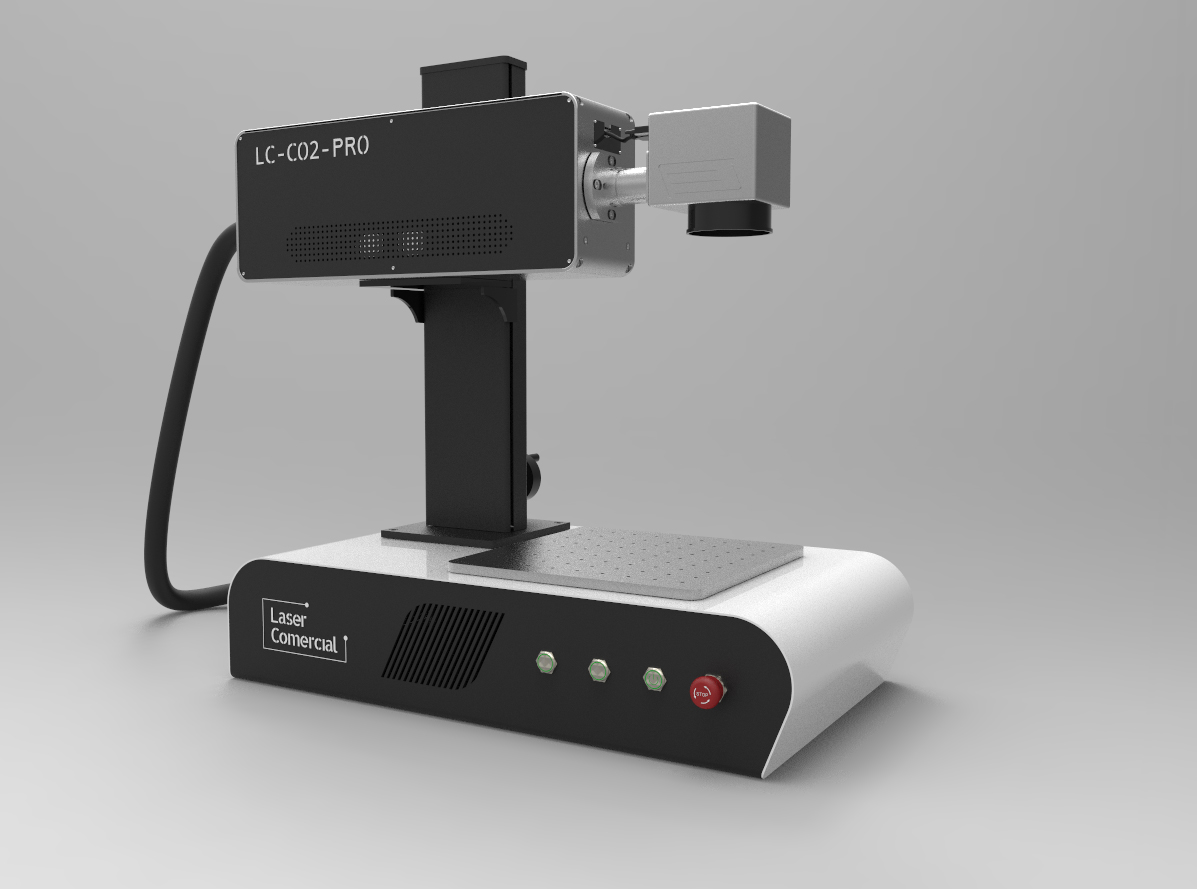

CO2 Laser Systems

CO2 laser engraving machines are perfect for permanent and quality engravings on different types of surfaces. The laser beam of the Co2 laser marking machine offers an extremely low tolerance, which is not only more productive, but also much more precise. It is more environmentally sustainable, other types of lasers can only convert a small percentage of the power of your power supply into photons, but a Co2 laser converts around 40-60% of the energy it consumes. It has a lower maintenance cost, the CO2 laser marking machine. It does not require high maintenance, so we reduce costs and improve production efficiency. The ease of use of this machine stands out.

The CO2 laser marking equipment only needs to design the cutting patterns on the computer, and you can mark the design you want. It is possible to implement engravings of different shapes and designs such as letters, codes, logos, drawings or shapes. Our marking systems have a serial and/or USB 2.0 connection for data transfer, this facilitates communication between the user’s PC.

What materials can we engrave?

CO2 laser engraving machines are highly versatile due to the fact that there are many materials that we can work with them:

Wood . One of the most interesting materials, since wood allows us to engrave and cut with a laser to carry out our best designs.

Plywood or MDF is widely used due to its low cost, but bamboo could be a more environmentally friendly option to work with.

Acrylic and Plastic. To make some designs we could be interested in cutting or engraving acrylic or similar, letters could be cut, codes, ornaments, jewelry, among

other options could be implemented. Also, there are many types of acrylics and plastics that we could work with with a CO2 laser .

Glass. In the case of glass we could only engrave it, but not cut it. We can decorate ashtrays, wine glasses, glass figures, to give a few examples.

In addition, with the rotary accessory it is ideal for engraving cylindrical objects, such as bottles or the like.

Leather. It is possible both to cut it and to engrave it. Interesting for making leather labels and accessories and establishing designs or words,

we could also customize wallets, bags, signs, belts, works of art, among others.

Rubber gum. It’s not very well known for use with laser machines , but it is. Basically we would highlight the use of the CO2 laser machine

in rubber to make our own stamps, which are used to put the address,

the date or the logo of our company. And not only this, we can discover other possibilities that rubber offers us.

Metal. Although it is not the most suitable material for cutting with a CO2 laser, it is more suitable for engraving and

implementing our designs on different metal surfaces.

Paperboard. A very economical material and suitable for both cutting and engraving. Interesting to

design prototypes, boxes with our logo, among other options.

Paper and cardboard. These two materials are also very cheap and offer many possibilities, some examples could

be: business cards, drawings to paint, painting templates, etc.

Marketing industry. It allows us to record company logos, names, business cards and all kinds of materials that

allow the dissemination or recognition of your company in the market.

In conclusion:

After knowing a little more about both systems, we can conclude that each system has its pros and cons. Having in mind that the CO2 laser is an older technology and that the fiber alternative in recent years has gained ground thanks to the speed of its operation, considerable cost reduction and higher performance than CO2. Now that we know more about both, it all depends on the types of work in which you want to use it, the types of applications you want to run and the sector where you want to use laser machines, you should choose which one suits you best.