This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Can we engrave ceramics with a CO2 laser?

Summary

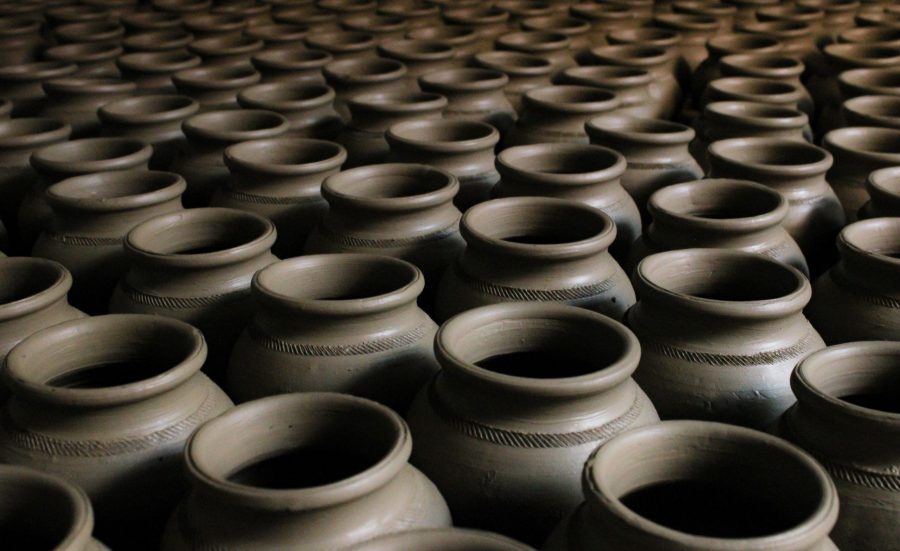

Pottery is made from clay, sand, or other similar materials. The time it takes to make pottery or porcelain largely depends on the materials they are made from. Some types of common ceramics contain alumina, porcelain, zirconium, earthenware, silicon carbide, and ceramic tiles. Ceramics provide good thermal and electrical insulation properties.

Ceramics are components that are both hard and brittle. Also, it is usually used to make the desired solution by adding color to them. In this case, it has to withstand high temperatures during its preparation, so it is placed in an oven designed for this purpose.

In this blog, we will clarify doubts about whether we can apply laser engraving or laser marking on ceramics, a material from what we have seen is usually very fragile and delicate. Knowing from the beginning the quality of LaserComercial machines and the high level of efficiency in their work and results.

Application of laser engraving on ceramics:

The laser engraving procedure on ceramics is usually done with Co2 laser machines . If we talk about laser engraving , we can say that it is a very versatile technique that allows us to process multiple materials with the same equipment. CO2 laser systems are ideal for ceramic and porcelain engraving or marking . They stand out for their high precision and thus facilitate the laser engraving of extremely precise illustrations and the finest lettering. Through non-contact laser machining the material is protected and breakage is prevented. This process produces a lightly textured surface that can be used to create intricate patterns and detailed images.

These laser machines use simple software and connect to the device through our laptop. We can configure the parameters that best suit the application and the material that we need to laser engrave. Laser engraving allows us to make permanent marks on our products. We can implement prototypes, corporeal letters or personalization of objects. So thanks to this, we can use the same laser for different types of engraving, and we only need to edit the different types of parameters of the laser machine .

Benefits obtained from laser engraving machines on ceramics:

Laser machines can be an innovative system for many sectors and companies . It is an efficient and useful technology in different industries . Because it is a new procedure in the market, many companies are not aware of the numerous advantages that laser machines offer . In this case we will focus on laser engraving and marking machines , which unlike the traditional alternatives that currently exist in the market, the laser presents a very advanced system and that in recent years has been the preferred by the workers or companies in these industries.

Because we are the ones who take care of the entire manufacturing process of laser machines, we can guarantee you the best quality in the sector. We can highlight some key advantages of using laser engraving on materials as delicate and fragile as ceramics in this case. Here are some of the benefits:

- No tool wear

- Very high precision in laser marking

- Perfect for brittle materials such as ceramics.

- It does not cause waste in the environment of the place where the engraving was made.

- High repeat accuracy with consistent engraving quality

- Laser engravings with a high level resolution and quality.

- Possibility of different contrasts depending on the power of the laser

- Long useful life of LaserComercial machines, which allows to reduce costs in the long term.

- Does not emit pollutants and toxic substances.

- Maximum speed and power performance

- The laser engraving is indelible and durable.

Other materials that we can also laser engrave:

We know that laser engraving machines are versatile due to the large number of uses that we can give them, that includes the enormous list of materials to which we can apply this system apart from ceramics. These materials only require the manipulation of the parameters for their respective application in each of them . We will highlight some materials that we can engrave with a CO2 laser machine, the applications in the materials where you want to use this technology or the sector where it suits you is left to your discretion. If you still have any questions or want to ask us something, we can provide you with advice to help you clarify any question you have in mind. Some of the materials that we can work with laser engraving machines are usually:

- WOOD

- ACRYLIC AND PLASTIC

- CRYSTAL

- LEATHER

- RUBBER RUBBER

- METAL

- PAPERBOARD

- PAPER AND CARDBOARD