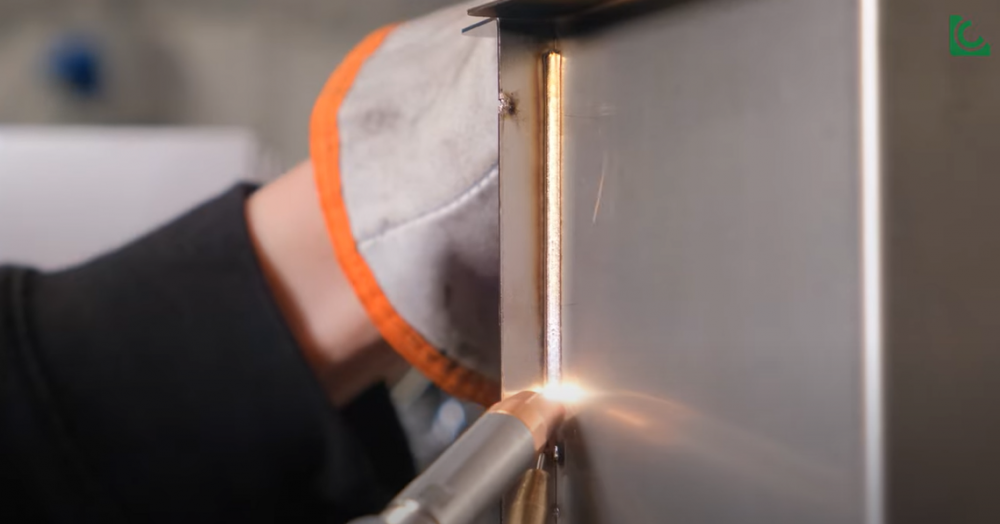

Laser welding for stainless steel containers

Summary

Stainless steel is a kind of steel with strong corrosion resistance, because the chromium or other alloy metal contained in this kind of steel has a strong affinity for oxygen and reacts with oxygen to form a passivation layer, preventing thus the corrosion of iron. Stainless steel is also highly valued for its hygienic properties, allowing it to be applied in the medical field.

Laser welding is a clearly viable alternative for welding this type of steel , taking into account all its benefits and the speed of its processes. Laser welders feature a fiber laser . These types of lasers are more than perfect for welding parts and machinery made of stainless steel . Due to all these advantages, acceleration of production processes can be achieved.

Stainless steel is a widely used metal in many industries and is traded in many markets. Stainless steel is defined as a steel alloy that may contain other types of metals such as molybdenum, nickel or tungsten. In this article, we will introduce the application of laser welding to vessels made of stainless steel in detail. Throughout this article we will define what stainless steel really is, some examples of the use of laser welding with this type of steel and some example videos.

Stainless steel pools:

Pools made of stainless steel are the least known in this industry, but not for that reason a less beneficial alternative than the others.

Stainless steel pools are those where the walls are made of steel, the floor is made of concrete and where the whole is lined with a material that makes it watertight. The part made of steel is joined with welding, in this case if you want a fast, simple process and with the best results, you can go to laser welding machines because laser welding machines are configurable equipment and adaptable to each job. They offer the possibility of welding with material contribution if required with an automatic wire feeding system .

If we talk about the advantages of stainless steel pools, we can start with the weight: steel pools are lighter than a construction pool, which makes them perfect for surfaces that are not able to support too much weight, such as attics. The weight characteristic also makes these pools easy to transport, which is not the case with prefabricated pools. The structure of a steel pool can be for life, if the material used is of quality. As it requires a resistant welding, in this case we can take into account the alternative of laser welding .

The manufacture of these pools usually takes around 9 to 10 days due to the different processes that their manufacture specifically requires. But thanks to the speed of laser welding machines we can speed up the processes.

Cookware:

In kitchen utensils, stainless steel is one of the most used materials for its manufacture, both at a domestic level, in professional catering, and at an industrial level. Because it is mechanically strong, it is chemically resistant to corrosion, easy to clean, disinfect and sterilize. Stainless steel comes in many varieties, with different compositions and properties, and this is often a source of confusion and concern when choosing tableware and cookware for our kitchens.

Thanks to laser welding we can achieve perfection in kitchen utensils due to the low heat input that is provided . Thus, it is possible to save more than 80% of energy compared to arc welding . In this way, the processing cost is reduced up to 30%.

The fast laser welding speed and minute warping of the workpiece will require only one process without the need for secondary processing. Laser welding is involved in many of the appliances that we have in the kitchen. We can find it in the production of the lining of the oven and microwave, in the extractor hoods and in the process of creating the simple faucet and pipe.

Advantages of laser welding in the manufacture of stainless steel containers:

An advantage of using laser welding machines for these jobs is that it is much faster than other welding methods such as TIG or MIG. In addition, the result is high quality welds and very good resistance. Welders can work faster and in better conditions doing much more efficient work. Companies are increasingly using laser welding equipment in the processing and manufacturing of all kinds of utensils. This equipment can benefit all types of audiences, since it overcomes the limitation of being a team only for companies due to its ease of use.

Some clear examples of their respective advantages would be:

- Great precision of the laser beam, allowing high quality and durable welds

- high welding speed

- Possibility of making complicated welds

- Little heat transfer, so the areas surrounding the weld are not affected

- Wide variety of laser weldable materials

- More comfortable and easy-to-use equipment compared to other more traditional welding techniques

- little welding deformation

- Does not require a review process