Laser marking, the main alternative in the jewelry sector

Summary:

The commercial activity of this sector focuses on the trade of all kinds of jewelry.These are items used as decoration or personal adornments. The most used materials to make this type of personal adornment are metals, whether they are precious metals or base metals. The first being the most outstanding due to the high economic value, its limited quantity of existence and its ductility <<Easy to work to change its shape>> .

On the other hand, we can say that what is most expected from a jewel apart from its aesthetics is its durability . Which needs to be accompanied by quality markings that are not damaged over time. Currently there are several traditional methods to perform this type of function, but lately companies in the sector are choosing to acquire laser systems.

Because they are very versatile equipment, since they allow different types of work to be carried out, for example: marking of expiration dates, marking of QR codes, engraving of tools, marking of bottles, implementation of logos on different metal surfaces, among many others. options. In this blog we will tell you about all the advantages of laser machines focused on jewelry and the reason for their high demand.

Laser marking applied to jewelry:

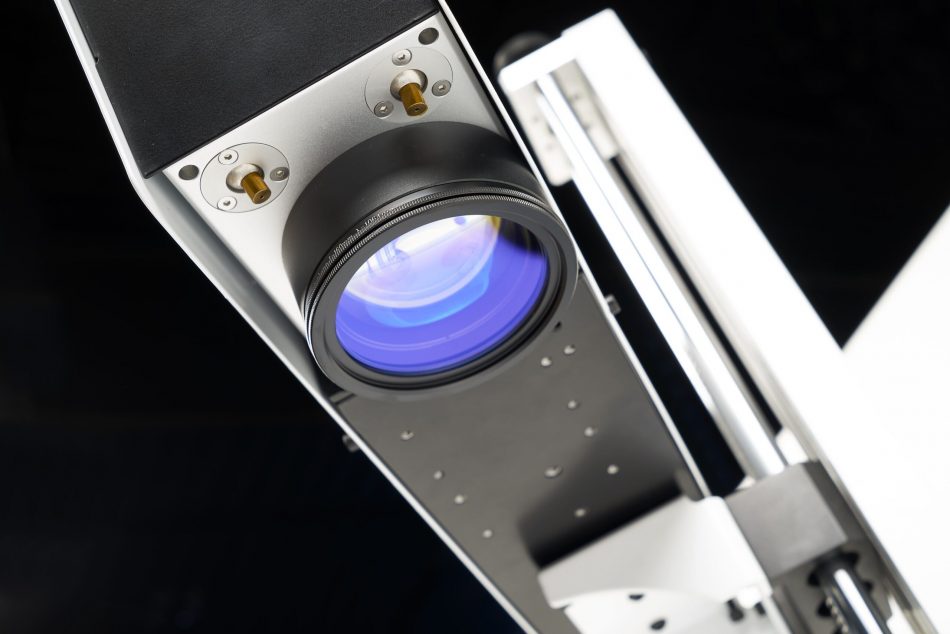

Laser technology allows marking both serial numbers or authenticity or anti-counterfeiting codes, as well as ornaments or photographic engravings, in record time, respecting the properties of the jewel and with maximum precision. These laser machines allow you to quickly mark and engrave in great detail.

Laser marking machines serve us as a method to give jewelry an extra personalization. This method allows us to implement creative designs in jewelry pieces easily and with quality on different materials. The design can still be something created specifically for each client, but the fact of using the laser to implement these designs, makes the work of the jeweler easier.

Personalized jewelry can be a very profitable idea to develop with a laser marking machine ; applying famous phrases or personalizing in high quality.

Jewelry laser marking machine systems are increasingly taking their place, replacing traditional methods. One of many reasons is that jewelry laser marking allows a multitude of shapes and materials to be machined with extreme precision, speed and durability.

LaserComercial specializes in laser marking machines in which we have laser marking machines that can be used to mark and engrave items such as rings, bracelets and watches.In addition, we always strive to meet productivity requirements. Lasers can also cut thin metals for necklaces, initials and names, and other intricate design cuts with great precision.

Key benefits of laser marking on jewelry:

Infinite applications: Due to the versatility of laser marking machines in the jewelry industry, it allows us to carry out applications in innumerable types of metals, which increases the production options for the manufacturer.

Growth in manufacturing methods: It serves to speed up billing processes by providing a legible and effective result.

Optimum results: Laser marking allows the result in the pieces with perfect and clean finishes. In addition, savings in the use of the material and the increase in production speed due to the long useful life of the machines and the speed of the processes.

The laser marking machine requires a different configuration depending on the type of material we are engraving or marking. This setup is not difficult to do.

Some examples of jewelry that we will have to laser mark in the jewelry sector can be: Necklaces, Bracelets, Bangles, Wedding Rings, Commemorative Rings, Badges with inscriptions, Watches, Key Rings, Amulets or Corporate Gifts.

See table of the different metals:

| Precious metals | Base Metals |

| Gold | Copper |

| Platinum | Tungsten |

| Palladium | Titanium |

| Rhodium | Iron |

| Silver | Zinc |

| Nickel |

Other applications of laser marking:

Knowing the versatility of laser marking equipment , we can come to the conclusion that the number of types of objects and materials that we can engrave and mark with lasers is limited to the imagination and creativity of the operator, always depending on the purposes for which it is desired . do serve laser marking machine.

We can also say that through ” laser marking ” we achieve different finishes on the materials depending on the procedure and the configuration that we carry out, we can execute more and less deep markings, marks of different shades, among other options. Next, some videos that demonstrate how the laser works for the marking of some surfaces.