This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Frequently asked questions about laser cleaning

Summary:

This technology is the newest development in the area of cleaning different types of surfaces or materials. LaserComercial designs and manufactures the LC-CLEAN, a high quality equipment with a series of potential advantages compared to all the traditional methods that we can currently find in the market.

If you still don’t know too many things about the laser cleaning system or you don’t trust this technique, this is the perfect article to provide you with all the necessary information you need to learn more about this impressive technology.

In this article we have collected the most frequent FAQs about laser cleaning. A quick and easy way to learn about this technology and solve the most general doubts that come to us.

How does the laser cleaning system work?

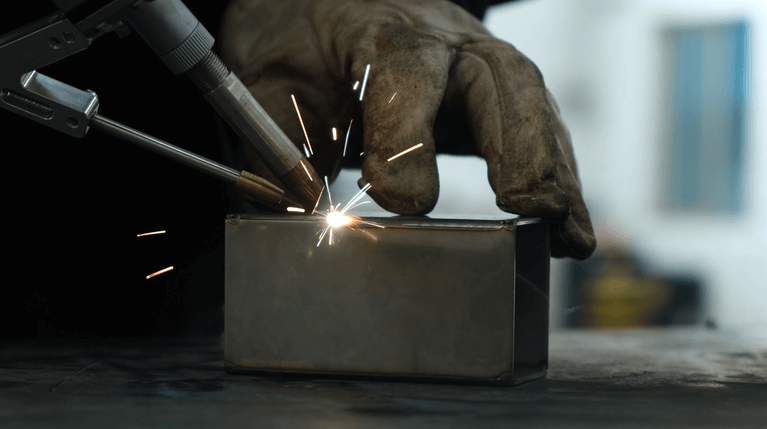

LASERCOMERCIAL laser machines are equipped with high quality fiber lasers. During laser cleaning, the light beam generated by the laser source is directed through a fiber optic cable to a reflector system that emits the laser in the desired shape and configuration.

The highly concentrated radiation at the surface causes the evaporation of impurities from the material. These impurities are vaporized by ultra-short laser pulses that cause very high temperatures and pressures. Thus, the substrate is not damaged during laser cleaning. It is a non-abrasive, non-contact cleaning technology.

The most interesting thing about this laser device is that the laser beam and wave frequency can be adjusted depending on the work to be performed. In this sense, with the above explanation and some acquired knowledge, it is very easy to use this device.

What advantages does laser cleaning provide compared to its conventional alternatives?

This cleaning technique is suitable for many types of work due to its great versatility and different possible applications. The LC-CLEAN is a high-end equipment, which has the following benefits:

- Altamente eficaz, que es lo que convence a muchos usuarios, con la limpieza láser podemos limpiar muchos tipos de suciedad, incluso el óxido.

- Máquina muy fácil de usar, con un poco de formación podrá trabajar y utilizar el equipo láser desde el primer momento.

- Comparado con otros métodos de limpieza, es más rápido y rentable.

- Es un proceso respetuoso con el medio ambiente. En otras palabras, la limpieza láser no utiliza productos químicos ni sustancias nocivas para el medio ambiente y no produce exceso de residuos.

Are consumables required for laser cleaning?

When opting for efficient cleaning solutions, it is also necessary to take into account the extra costs that these may have, such as consumables. A factor that in some cases can considerably affect company budgets.

A great advantage of laser cleaning machines is the fact that the number of consumables used is considerably reduced compared to other alternative methods.

What are the differences compared to shot blasting?

Actually, the cleaning market has evolved, but many of the techniques used are still backward, since they use manual processes combined with aggressive chemical products that damage the material to be cleaned.

In addition, some techniques, such as shot blasting, have some disadvantages, for example, the need for a large workforce in the various stages of the manual process. With laser equipment we achieve great advantages such as a very fast preparation of the cleaning process.

Some research has shown that the time is reduced up to 20 times compared to other cleaning systems. The laser cleaning equipment has a high speed, dry cleaning and is also environmentally friendly.

How to operate the laser cleaning machine?

The LC-CLEAN laser cleaning equipment is controlled by means of a touch screen located on the front of the equipment, so that it does not require any computer or external complement for its control.

The configuration of the parameters is done through the touch screen, in which you will find options to vary the power, frequency or width of the laser and the length or width of scanning. The control panel has more functions that allow you to configure the machine depending on the work you want to do at that moment. Functions such as the graph or direction of the laser.

A laser machine must be properly configured, both in software and hardware and the machine parameters just before working. In this way the equipment can absorb the dirt (rust, grease, paint, glue, among others) of a surface and where the laser ablation occurs there is not enough energy to damage the substrate, but only affects the impurity of the surface of the material.

How many types of laser cleaning machines are there?

The lasers of the different models are distinguished by their power. We have lasers of different powers depending on the work to be done or the speed required to work on an application. That is to say, some aspects that will make us choose some equipment over others are: the amount of dirt we need to remove, the material on which we will work, the type of dirt or impurity we need to clean, among other similar aspects.

It is noteworthy that, being configurable equipment, a high power machine could work as a lower power machine with the appropriate configuration.

Thus, we have laser cleaning equipment of 140W, 200W and 500W. We highly recommend to consult with one of our experts depending on the work to be done.

Materials

| |||

| Oxide | ✓ | ||

| Resin | ✓ | ||

| Stains | ✓ | ||

| Dirt | ✓ | ||

| Coatings | ✓ | ||

| Painting | ✓ | ||

| ✓ | ||

In which sectors or industries can it be applied?

Laser cleaning equipment can be used for many types of applications, depending on the sector or industry in which it is used. It can be used for large scale jobs such as structures and at the same time be used for smaller jobs that require a more rigorous level of precision such as cleaning small metal parts of machines.

- Weld cleaning. It is increasingly common to use laser machines to prepare materials to be welded or to clean welds with a laser without affecting its resistance or damaging the material.

- restoration . With laser we can clean buildings, monuments or structures without major damage.

- Removal of rust or corrosion . Oxide layers respond very well to laser light and can be easily removed. It is also interesting to use the laser to clean parts or surfaces that have been exposed to the elements for a long time.

- Cleaning of Paintings . With laser cleaning it is possible on walls, metals and other surfaces. It is relevant for removing coatings to prepare a surface for applying a new coating.

- Cleaning of grease and oils . Within an industrial production process, it is an efficient way to clean pieces and parts of machinery within a manufacturing and production process.

- In any place where a deep and quality cleaning is required.