Laser marking of iron cowbells with brass plating

Summary:

The basic fiber laser marking equipment allows us to perform marking with a high level of precision on different materials and surfaces. Our equipment is easy and fast to use. It does not require a high level of specialization so that with a simple training the laser equipment can be put into operation without previous experience.

In this case we put the LC-FIBER to the test, making deep and sharp marks on brass coated iron at an incredible speed, implementing various designs on cowbells.

If you want to know more about laser marking and its advantages, continue reading the article. If you have any doubt or interest in this type of application, you can contact us through any of our contact channels.

Laser marking on iron surfaces

One of the main advantages of laser marking equipment is its versatility. That is, it allows us to perform a wide variety of markings of different sizes and shapes, on various types of materials or surfaces.

Among these materials, iron is characterized by being a hard and tenacious material. This is often an important factor that affects the speed of marking in other alternative methods. As we can see in the video, the speed of laser marking is at an incredible speed that is difficult to achieve with other methods.

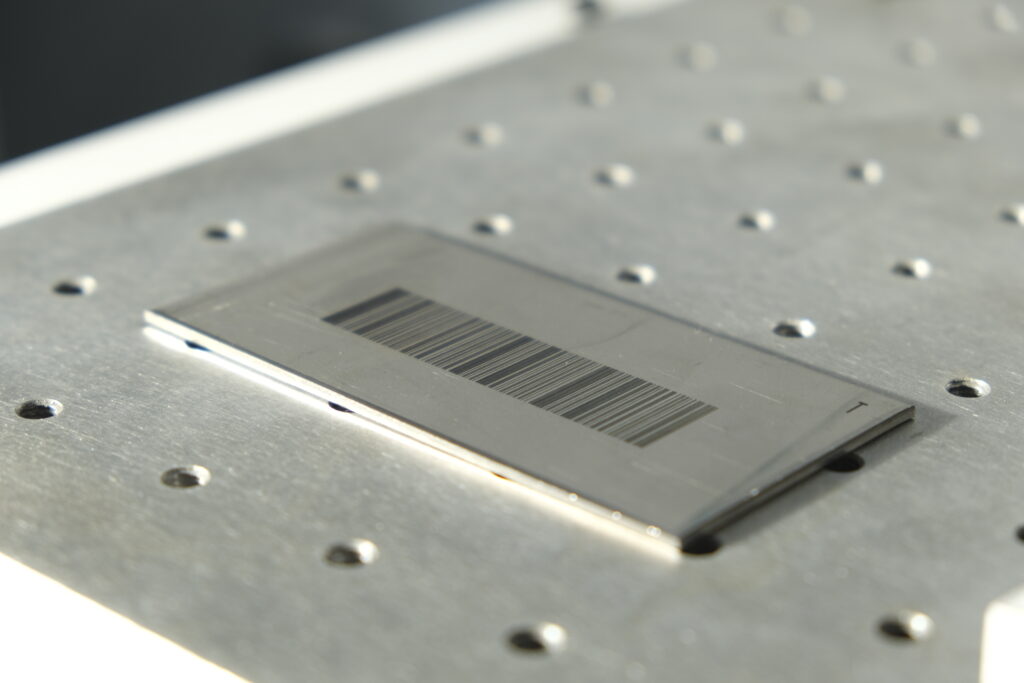

In this video we achieve deep and sharp marking on brass coated iron at high speeds by implementing designs on cowbells. LC-FIBER is applicable to a wide variety of sectors and industries, both in a more decorative design field and in situations where you want to increase the traceability of a company’s products by implementing QR codes, DataMatrix, barcodes, references…

Wide range of applications with the laser marking machine:

In other sectors, laser marking offers many options, since it is a very versatile and efficient equipment. In addition, it is an environmentally friendly equipment due to the minimum amount of consumables required for its use. It is a turnkey project, there are models of fiber laser marking machines ready to be integrated into a production line and chain productivity.

Expiration date marking. With laser marking, you can forget about glue and inks that print the expiration date. With laser marking, it is very easy to mark small areas on different products. In the same way that we can mark dates, it would be possible to use letters and different vectors.

Data matrix. One of the main industrial applications of laser marking is data matrix. Lasers save us time and costs, they are fast devices, with few consumables and little maintenance. Laser markers combine a highly accurate and reliable system configured with user-friendly software.

Barcode and QR code marking. As mentioned above, the surfaces to which laser marking can be applied are very diverse. We can facilitate code reading with high quality fiber laser marking. A wide variety of QR codes, as well as digital codes, can be applied to keys, locks, labels, etc.

Logo marking. Many companies choose to apply small symbols to their products to give them a personal touch. We can mark logos, letters, signs that add a unique touch to the finish of the products. Many companies also use laser marking to combat counterfeiting.

Marking of electronic parts and components. Laser marking is also used to distinguish between different components of electronic equipment. There are many laser options, so any company can find a laser marking application that makes their job easier.

Marking to check the conductivity of components. Laser technology can be used to test the conductivity of metal with a paint coating. This allows us to perform these tests quickly and with excellent results, as the marking we leave on the material is as accurate as possible thanks to the precision of the laser marking.

What are the benefits of laser marking?

- High precision markings. Very good quality markings and engravings can be made.

- Easy to use. It does not require a high level of specialization by the operator. By means of a short training we could start up the laser equipment.

- Integration in production lines. This equipment can be easily integrated into production lines.

- Non-contact processes. Laser technology allows working cleanly, without contact or affecting the surrounding areas.

- Great control. Laser marking machines are highly configurable, allowing to achieve the most required result for each job.

- Different types of marking. The versatility of the marking machines is incredible. You can work with all kinds of marks and shapes: images, QR codes, dates, logos, geometric shapes, among many other options. And it can be implemented on different materials with different techniques.