Why is the industrial market adopting laser engraving?

Overview:

Laser engraving has never been easier for industrial applications, whether it is to personalise specific products, protect brand ownership and have a higher level of security.

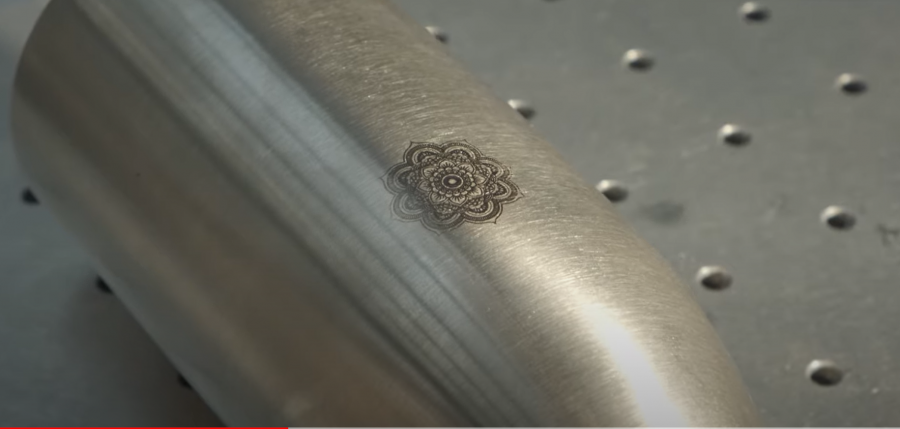

What is laser engraving? It is a laser beam that physically removes a layer of material exposing a cavity that reveals an image that the eye is able to see. It is a very versatile technology because it allows us to work on a wide variety of materials with the same equipment. With this machine we can implement all kinds of brands, but above all the industrial sector looks for it to provide controls and verifications against counterfeit products or replicas.

The laser head does not have to be positioned at the point where we want to mark, but two mirrors located at a greater distance from the material are used which rotate quickly and reach the positions of the material to be marked more quickly. Normally they are desktop machines, adaptable to different types of spaces and industries. These laser machines work with a simple software that will be connected to the equipment through our laptop. We can configure the parameters that suit us best for the application and the material we need to laser engrave. In this way, we can perform different types of engraving with the same laser, just by editing parameters such as the speed or the width of the laser beam.

What is the difference between laser marking and laser engraving?

Laser marking can be seen at a glance, they are very superficial marks that, if you run your finger over them, you won’t notice anything. Laser engraving, on the other hand, has a deeper impact, visible to the eye as well as to the touch. Laser engraving, implemented with a CO2 laser, is more useful and offers greater engraving depth on specific materials.

This laser technology allows us to work with different materials and carry out a wide variety of jobs such as personalisation, labelling, decoration, jewellery, pattern making and templates, fabrics, traceability and references. With laser engraving machines we can have a very high precision that allows us to make detailed and clear images to implement the design we want, which cannot be altered. It is ideal for credit cards, ID cards, sensitive documents and other items that require additional security measures.

This is why industrial companies look to this type of machine for their operations, as it can provide engraving of serial numbers, dates and times, part numbers, component labels, data matrix code markings, trademarks and industry specific codes. High quality engraving allows the engraving to be read by barcode scanners, RFID scanners and other inventory tracking tools.

What laser engraving looks like in industry can become a very important tool in part identification and product security. As a result, many industry segments, including robotics, 3D printing, inventory management, banking, security, government agencies and the automotive sector, are beginning to turn to laser engraving to provide an additional layer of security.

Benefits of laser engraving

The top four benefits of laser engraving are as follows:

- Speed: The speed of the Galvo system can be very high. Fast, quality engravings are achieved on stainless steel, machine and tool steel, bronze, copper, nickel, silicon, titanium, aluminium and many more.

- Maintenance: Galvo CO2 laser engraving equipment generally requires much less maintenance than laser cutting and engraving equipment using computer numerical control (CNC) technology.

- Compact equipment: These machines generally occupy a smaller volume, they are desktop machines. This means that they are more portable and manoeuvrable, they can be placed in different spaces. Equipment with everything integrated with a plug and play system and USB connection to work easily.

- Versatility: With the laser engraving machine we can work with a wide variety of materials and apply this technology to different purposes and jobs in different industries regardless of the size of the product to be engraved. We can take advantage of the full potential of laser technology to improve our production.

Start engraving!

If you need more security to prevent fraud or intellectual duplication or speed up the engraving of codes, trademarks or any other need, do not hesitate to switch to laser engraving. At LC Lasers we will advise you on the best for your work and product, we will provide you with the best machine adapted to you with an ease of use that will not require a great effort or a lot of training.

For more information you can contact us and a technician specialised in laser marking will contact you to help you with whatever you need.

A variety of applications

A remarkable aspect of laser engraving machines is their versatility. An important factor when purchasing laser marking and engraving equipment. With the LC-FIBER we have access to a wide range of applications on different materials and surfaces. This depends on the power we choose and the speed at which we want to mark.

- Personalise parts and tools

- Implement logos on locks or keys.

- Marking important information on industrial parts.

- Coding medical equipment.

- Marking manufacturing or expiry dates.

- Personalisation of jewellery.