Laser marking on tools

Summary:

Laser tool marking is permanent and offers a perfect traceability system. In this case, the laser marking machine offers significant advantages over alternative methods. Laser marking of metal tools is very durable and provides excellent flexibility.

Laser marking can be applied with great precision to tools of different geometries, even with very small character sizes. It is a system that does not damage or alter the piece to be marked, as the laser treatment is non-contact and chemical-free.

Thanks to the environmentally friendly treatment, there are no additional cleaning costs.

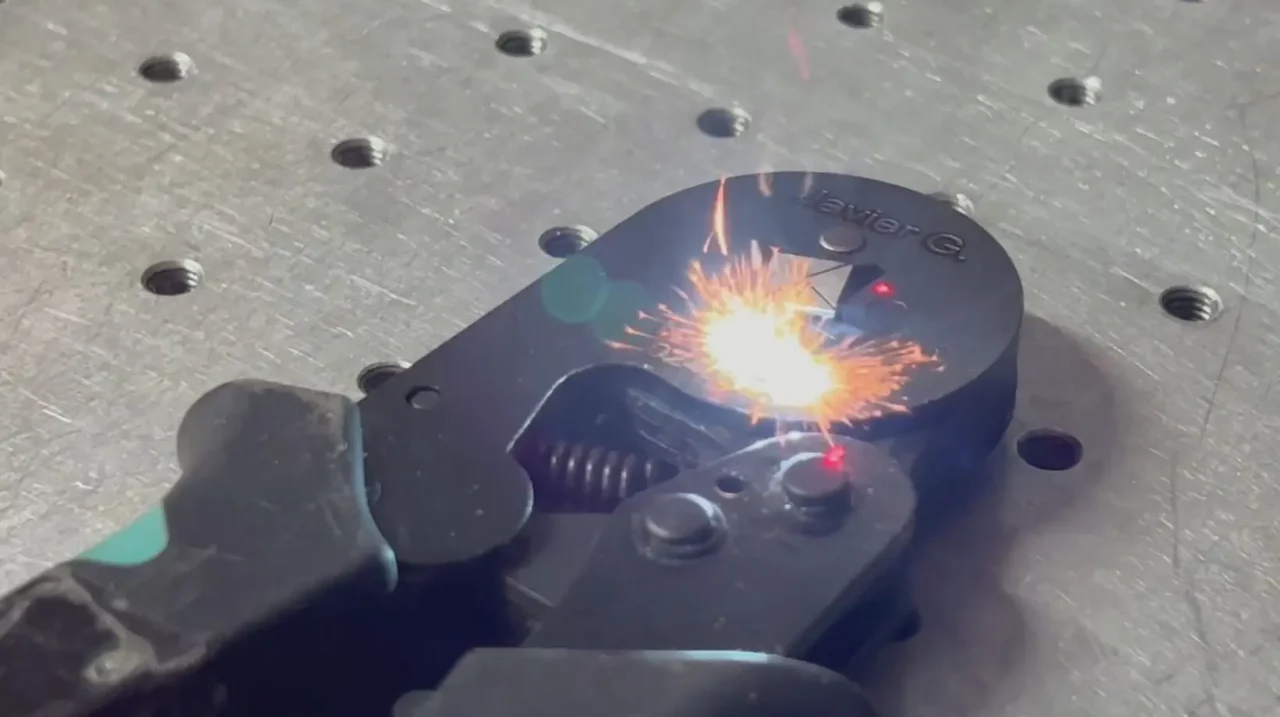

Applying fiber laser marking machine on tools

LC-MARK machines are perfect for fast marking and engraving. The laser marking allows us to permanently mark a surface at an incredible speed, it is a model designed and manufactured exclusively by LC Lasers.

We can apply this system in the traceability of tools or components of different materials, mainly metals. In this case, we have used the LC-MARK to make permanent markings on tools commonly used in our workshop. You can appreciate the speed with which this equipment works, optimizing our production processes.

They are compact machines with everything necessary integrated to implement all kinds of designs: logos, drawings, barcodes, QR codes, data matrix, numbers, inscriptions, among many other options.

What tools can we laser mark?

For laser marking we can work on a wide variety of materials, such as stainless steel, carbon steel, aluminum, copper, PVC, among other materials. Any tool made of these materials can be permanently marked. In the case of marking on wood, the LC-CO2 laser engraving machine is recommended.

With laser marking we can access a wide range of applications of different shapes and sizes. We get different finishes on the materials depending on the procedure and the configuration we perform, we can run more and less deep markings, marks of different shades, among other options.

These markings can be a useful support when classifying tools by departments or groups within the same production area.

Advantages of laser tool marking:

The basic fiber laser marking equipment presents a series of advantages that make it a potential option compared to its alternatives. The quality of its processes is totally guaranteed, since we are the ones who manufacture the equipment, with first quality components and with the perfect laser for the marking solution.

The following are the main advantages of laser marking:

- By using laser marking systems, we can perform various markings at incredible speed.

- Easy and complete software. The equipment has an easy to understand and manipulate software.

- Option to mark different shapes and sizes. Such as logos, drawings, barcodes, QR codes, data matrix, numbers, inscriptions, among many other options.

- They are environmentally friendly machines, as they do not use chemical components or generate waste.

- Preview. It allows us to preview the area prior to marking to avoid any incident before marking.