Reasons to choose laser cleaning machine

Summary:

In this article we will discuss the main reasons why the industry has given up on laser cleaning solutions. At LC, we are aware of the magnitude of the impact of the laser solutions that we can provide through our laser equipment. First we will start by talking about our laser technology.

Laser technology is applied to many types of machines, such as laser cutting and engraving, laser welding, laser metal cutting or laser marking.

In the case of cleaning, it is a much more recent and innovative technology, with the latest generation of lasers on the market.

More and more companies and individuals are deciding to invest in laser cleaning machines for their businesses or cleaning applications due to their many advantages over other systems. Let's go into detail about why choose laser cleaning over other options.

LC-CLEAN Applications

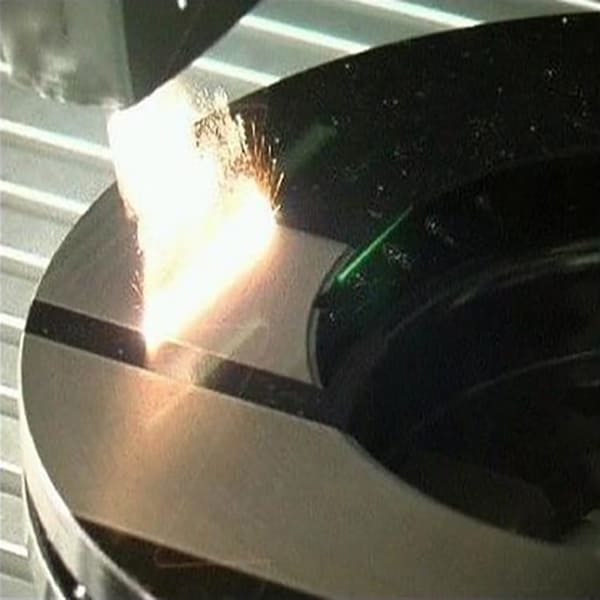

Our product range of laser solutions has been widely accepted in the industry. Laser cleaning equipment is very interesting equipment for different applications. Some examples of possible jobs to be done with a laser cleaning machine could be:

- Rust cleaning of different metal parts, machines or vehicles. The laser is capable of removing impurities from different materials, so removing rust is not a problem.

- Paint removal layer by layer. With laser cleaning equipment we can clean paint from different surfaces

- Clean various dirt such as accumulated food, grease or oils

- Cleaning of welds or preparation of materials to be welded, removing all impurities before working

- Removal of coatings and preparation of materials to apply new coatings or paints

Main keys to the success of laser cleaning machines

- Available in different models and powers: 200W and 500W. Especially at high powers, laser cleaning equipment can clean at surprising speeds.

- Laser cleaning machines have high quality fiber laser and high lifespan.

- Much more sustainable than using chemicals for cleaning or sandblasting

- They are devices with simple operability, easy to configure and comfortable. The laser machine has wheels that allow the equipment to be moved and the use of the laser gun is very comfortable.

- Configurable machines. Laser cleaners have a touch screen that allows you to configure the laser beam and the power used in each job.

- Control and emergency buttons. Each laser cleaning equipment also has an independent control system and a safety stop system in case of emergencies.

- Pneumatic wheels. LaserComercial's laser cleaning machines feature sturdy pneumatic wheels to improve the movement and versatility of the laser machine.

Ventajas de la limpieza láser

- Limpieza sin contacto y sin dañar el sustratoo material que estamos limpiando

- Limpieza precisa y concreta, además de limpieza selectiva si se requiere

- Sin consumibles ni contaminantes

- Eficiencia y eficacia.Equipos que hacen ahorrar tiempo de trabajo e invertirlo en otras tareas. Además, son equipos muy resistentes que a la larga salen muy rentables.

- Poco mantenimiento.Son equipos resistentes que no requieren demasiado mantenimiento

- Versatilidad y diferentes aplicaciones posibles.Además, la operación es muy simple, con la pistola láser se puede trabajar de forma muy cómoda y acceder y mover el láser como nos interese para realizar mejor la limpieza.