The Importance of Laser Welding in Steel at LC LASERS: Innovations and Advantages

Discover How Laser Welding Is Revolutionizing the Steel Industry with Its Multiple Advantages and Innovations

Laser Welding: Our Revolution in the Steel Industry

Laser welding has emerged as one of the most innovative and revolutionary technologies in the steel industry.

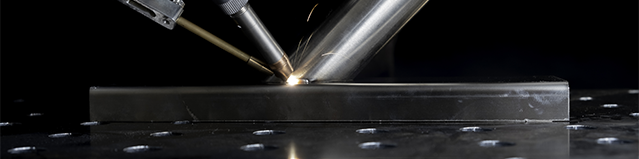

Unlike traditional welding methods, laser welding uses a highly concentrated light beam to melt and join metal pieces with precision.

This type of welding is particularly beneficial in applications that require high precision and control, making it an ideal solution for the steel industry. Additionally, it allows us to create stronger and more durable joints, reducing the risk of failures.

Advantages of Laser Welding in Steel

One of the main advantages of laser welding is its high precision, allowing for exact joints and minimizing material deformation. Additionally, laser welding is extremely fast, which boosts productivity and reduces manufacturing times.

Another significant advantage is the reduced heat-affected zone, which minimizes the risk of deformations and residual stresses in the material, ensuring greater structural integrity of welded parts.

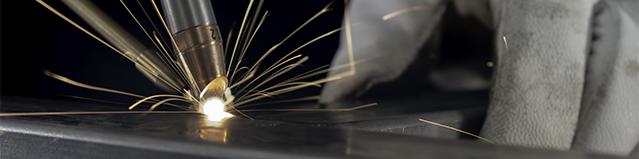

Recent Innovations in Our Laser Welding Machines

In recent years, our laser welding machines have seen substantial technological advancements that have enhanced precision, improved results, and increased repeatability in welding processes.

Furthermore, the latest generations of laser welding machines incorporate advanced monitoring and diagnostic technologies, facilitating early detection of potential failures and enabling real-time adjustments. These innovations not only improve weld quality but also increase efficiency and reduce operational costs.

Laser Welding Equipment: What You Need to Know

When considering the implementation of laser welding equipment, it's essential to keep several factors in mind. First, selecting the right machine to meet specific production needs is crucial. Factors such as laser power, the type of material to be welded, and the complexity of the joints should all be taken into account.

Investing in training for the personnel who will operate the laser welding machines is also important. Although these machines are highly automated, having a solid understanding of their operation and maintenance will ensure maximum efficiency and longevity of the equipment.