This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Laser Paint Cleaning: Techniques and Optimal Results

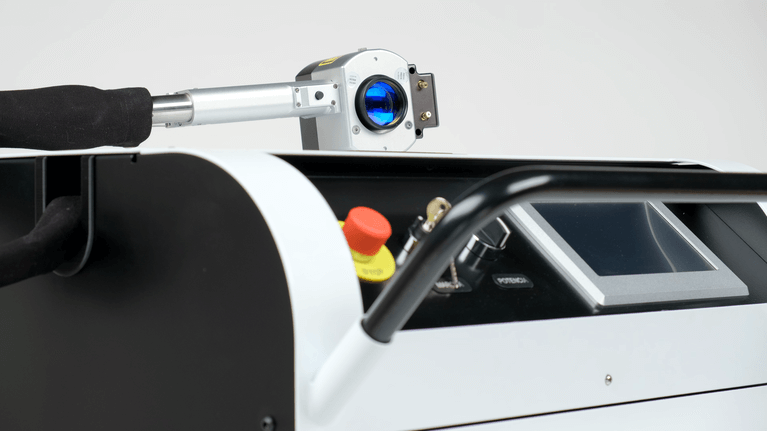

At LC LASERS, we specialize in the design and sale of state-of-the-art laser cleaning machines that enable precise removal of paint layers without damaging the underlying surface. This technology uses a concentrated light beam that vaporizes or decomposes the paint through a process known as laser ablation. Our machines are designed to work with various types of paint and materials, adapting to a wide range of needs thanks to an advanced control system that adjusts parameters such as power, pulse duration, and beam trajectory.

Laser Cleaning vs. Traditional Methods

Unlike traditional paint removal methods such as sanding, chemical solvents, or sandblasting, the laser technology offered by LC LASERS is less invasive and far more precise. Our laser cleaning machines avoid direct contact with the surface, reducing the risk of damage, and by not using chemicals, they are a more environmentally friendly and safer option. This technology is ideal for applications where precision and surface protection are crucial, such as in art restoration and the aerospace industry. LC LASERS machines provide a superior finish, faster cleaning, and a significant reduction in waste, making them the preferred choice for those seeking top-quality surface cleaning.

Safety and Preparation for Laser Cleaning

To maximize the benefits of laser cleaning, it’s essential to properly prepare the surface and adjust the laser parameters based on the type of paint and material being treated. LC LASERS machines are equipped with integrated safety systems and precise controls to ensure safe use; however, we always recommend wearing specific protective eyewear and following guidelines to avoid exposure to laser radiation, particularly on highly reflective surfaces. The features of our machines are designed to make the process both safe and efficient for the operator.

Key Factors for Optimal Results

LC LASERS machines are designed to allow adjustments to factors such as wavelength, power, and pulse duration, enabling optimal results in any laser paint cleaning application. The appropriate wavelength ensures maximum energy absorption by the paint without affecting the underlying material. Adjusting the power and pulse duration is essential for tailoring the process to each situation, ensuring effective and safe cleaning.

Practical Applications of Laser Cleaning

Laser cleaning technology has a wide range of applications and is especially versatile. LC LASERS machines are used in sectors such as the automotive industry to remove paint from body parts during repairs and refurbishments, achieving uniform and durable finishes. They are also ideal for restoration work, allowing for the cleaning of artwork and historical buildings without damaging the original material. In the aerospace and manufacturing industries, our laser cleaning machines are used to prepare surfaces before coating applications, ensuring optimal adhesion and contaminant-free surfaces.

At LC LASERS, we are proud to offer high-tech laser cleaning machines that combine precision, efficiency, and environmental responsibility, providing advanced solutions for the most demanding sectors.