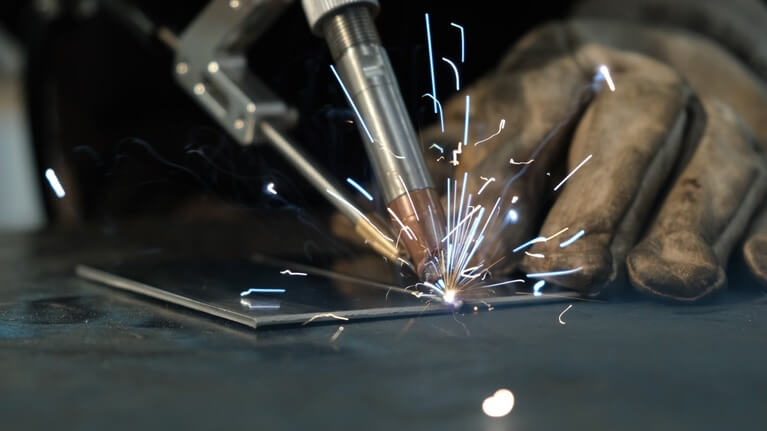

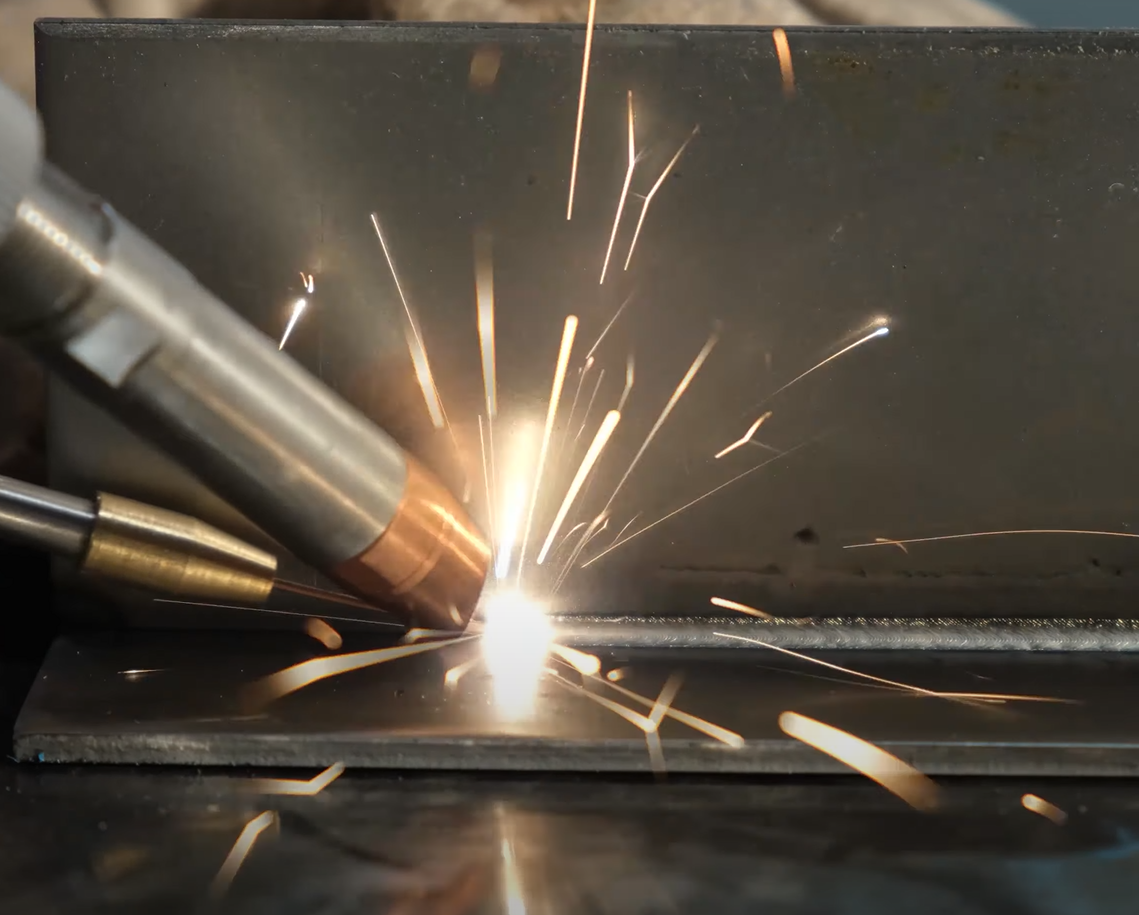

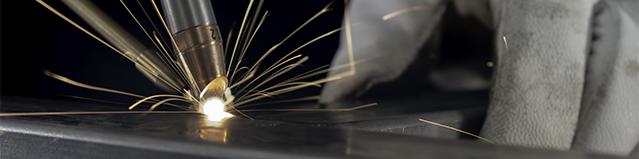

Discover the Materials You Can Weld with Our Laser Welding Machines

Summary

At LC LASERS, we are experts in laser welding technology, an innovative solution that offers precision, efficiency, and superior quality for a wide range of industrial applications.

If you’re wondering what materials our laser welding machines can handle, here’s a detailed guide on the most common materials and their benefits.

1. Stainless Steel

Stainless steel is one of the most popular materials for laser welding due to its corrosion resistance and its ability to maintain structural properties even after the welding process. With our machines, you achieve clean and precise joints, perfect for sectors like food processing and industrial manufacturing.

Advantages:

- Highly aesthetic joints without the need for post-processing.

- Low thermal distortion.

- Suitable for thin structures and complex tasks.

2. Aluminum

Aluminum is known for its high thermal conductivity and tendency to oxidize quickly, making it challenging for traditional welding methods. However, LC LASERS laser welding machines are designed to overcome these challenges, achieving strong and precise welds.

Advantages:

- Ideal for applications in the automotive and aerospace industries.

- Minimizes distortion thanks to thermal control.

- Capable of welding high-strength aluminum alloys.

3. Galvanized Steel

Galvanized steel has a zinc coating that protects it against corrosion, but this same coating can cause problems during traditional welding. Laser welding machines solve this issue with a highly localized approach, preventing damage to the coating.

Advantages:

- Clean and durable welds.

- Reduced emissions and spatter.

- Increased efficiency in fabricating coated metal parts.

4. Titanium

Titanium is a key material in industries such as aerospace and medical, thanks to its high strength and light weight. Our laser welding machines ensure secure joints, even in controlled environments to prevent oxidation.

Advantages:

- Compatible with controlled atmosphere processes to avoid contamination.

- Welds free of porosity.

- Ideal for critical, high-value-added components.

5. Carbon Steel

Carbon steel is widely used in sectors like construction and machinery manufacturing. With our machines, you can achieve fast and strong welds, even with varying thicknesses.

Advantages:

- High-strength joints.

- Suitable for large parts or structures.

- Consistent welding across different grades of carbon steel.

6. Special Alloys

Special alloys, such as Inconel or Hastelloy, present unique challenges due to their composition. Laser welding is ideal for these materials as it minimizes thermal changes that could alter their properties.

Advantages:

- Preservation of the alloys’ original properties.

- High precision for complex industrial applications.

- Extended lifespan of welded components.

Why Choose LC LASERS Laser Welding Machines?

At LC LASERS, we understand that each material has its own characteristics and challenges. That’s why our machines are designed to provide customized solutions that optimize every project. Laser welding not only improves the quality of joints but also increases productivity and reduces operational costs.

Benefits of working with LC LASERS:

- Advanced technology for a wide range of materials.

- Technical support and specialized consulting.

- High-efficiency machines to maximize production performance.

If you are looking for an innovative and precise welding solution, our laser welding machines are the answer. Contact us today to learn how we can help you take your projects to the next level.

LC LASERS: Innovation and precision in every weld.