Is it worth investing in laser welding services?

The evolution of the industry demands increasingly precise, fast, and sustainable solutions. In this context, laser welding has positioned itself as one of the most innovative and efficient technologies for material joining processes. But is it really worth investing in services or in a laser welding machine? In this article, we’ll help you find out.

What is laser welding and why is it revolutionizing the industry?

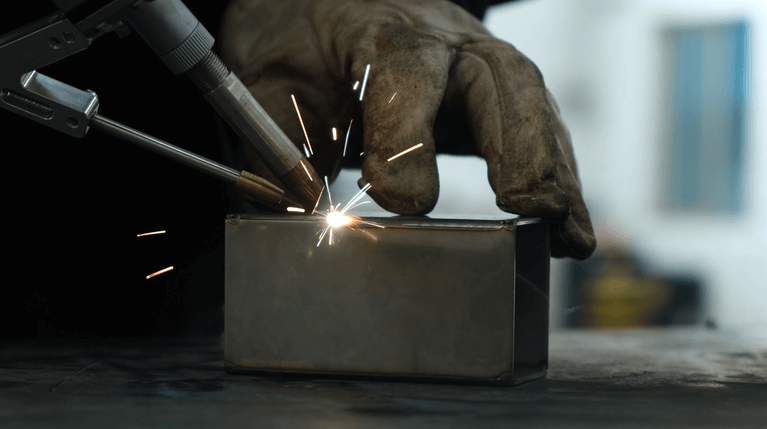

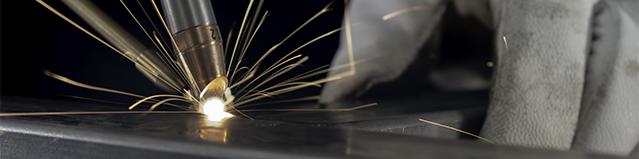

Laser welding is a thermal joining process that uses a highly concentrated beam of light to melt and join metal materials with millimetric precision. When the laser beam hits the surface, it generates a very high temperature at a precise point, allowing for fast fusion without physical contact.

Unlike traditional methods like MIG or TIG welding, industrial laser welding offers greater precision, fewer deformations, and a significantly higher work speed. It also reduces the need for rework, which translates into a significant improvement in productivity.

Advantages of industrial laser welding

Industrial laser welding not only represents a technological leap, but also a strategic tool to optimize resources and quality. Some of its main advantages include:

Precision welding: Allows working with small parts, complex geometries, and delicate materials without damaging the surfaces..

Reduced time and costs: Its speed decreases production times and operating costs.

Application versatility: From the automotive industry to jewelry, and electronics, laser welding adapts to a wide variety of sectors.

When is it worth investing in a laser welding machine?

If your company aims to improve final product quality, reduce manufacturing time, or increase competitiveness, investing in a laser welding machine can make all the difference.

The sectors that benefit the most include metallurgy, automotive, medical device manufacturing, electronics, and even metal art. The initial investment pays off quickly thanks to low maintenance, long equipment lifespan, and reduced costs due to fewer errors and rework.

In addition, return on investment (ROI) is often achieved within a few months if used consistently in production lines.

Why choose LC LASERS?

At LC LASERS, we don’t just sell laser welding machines; we provide complete solutions tailored to each client. Our experience allows us to understand the specific needs of each sector and offer custom-made equipment.

-

Specialized technical support: From installation to maintenance, our team supports you at every stage of the process.

-

Personalized training: We train your team to get the most out of the machines from day one.

We also work with cutting-edge technology, ensuring efficiency, durability, and professional results in every weld.

Laser welding is a technology that combines speed, precision, and versatility, offering unmatched benefits over traditional industrial welding methods. Laser welding machines not only improve productivity but also ensure a superior quality finish, ideal for the most demanding industrial environments.

At LC LASERS, we specialize in implementing advanced laser technologies. If you want to optimize your welding processes or explore the benefits of laser welding, contact us today. Our team is ready to help you transform your business.