Removing rust from production lines

Extending the useful life of our production systems can be essential in many industries. Avoiding renewing and changing meshes, carts, boxes and metal containers that we can use in the production of many products is important to avoid unnecessary expenses and save time. It is interesting to find cleaning and maintenance methods that allow to extend the useful life of these metal utensils that can be used on a daily basis. It is possible that over time, environmental conditions or maintenance some of these production elements will rust and corrode. Laser cleaning can be a great solution to clean and remove this rust.that can occur on many metal surfaces and can make it difficult to produce premium quality.

Oxidation in metals

Oxidation is a very common process that happens when oxygen reacts to certain environmental conditions. These changes cause the loss of electrons from a material, resulting in the formation of oxide on a surface, damaging the material in question. Sometimes, warehouses with high humidity, materials outdoors and exposed to rain and water, work with humidity and temperature changes can lead to the appearance of rust on metals . The corrosion of metals causes a significant loss of qualities of the affected surfaces, and may even break. For this reason and to maintain the quality of our metals, it is important to remove rust in time.

In many industries, metal meshes are used in their production lines or also containers, cars, doors and all kinds of objects and utensils made of different metals. In this case, it is interesting to use the laser to maintain the quality of our production.

Laser rust removal

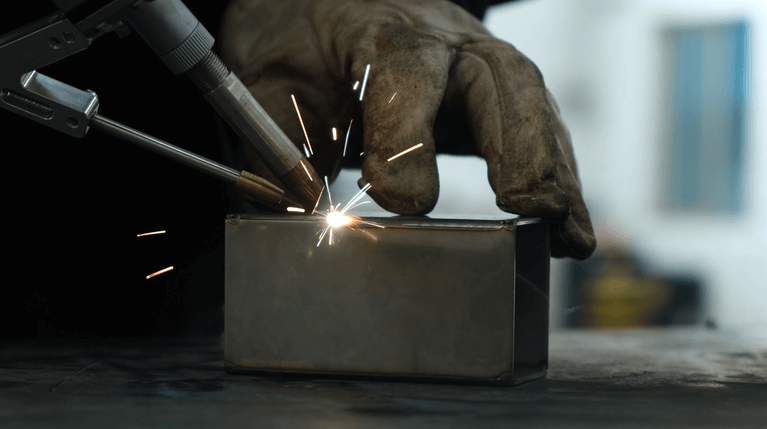

Laser cleaning is effective in removing corrosion from production lines with metallic materials. Focused fiber laser on a metal surface can efficiently remove impurities from a material without damaging the substrate. It is a contactless process, safe and very versatile. The cleaning laser is suitable for different maintenance and restoration work.

Laser cleaning machines can clean different types of surfaces and dirt, we will avoid the use of chemicals or more harmful processes such as sandblasting and generating waste. The user works with a laser gun that is configured from the equipment , we can adapt the power and the laser beam according to the work to be done. If the user wants to remove rust from different types of parts and surfaces, there is no problem, the laser equipment can be moved on a flat surface with its pneumatic wheels and work with the laser gun comfortably. Depending on the power of the laser machine, we can work with more or less intensity on dirt and impurities, these teams are available in different models.

The laser allows you to clean dirt such as: rust, grease, paint, coatings, clean welds, prepare materials for subsequent processes , among other options.

In addition, in this article we have highlighted laser cleaning applied to production lines, but the truth is that this technology can be adapted to many industries, for example:

- Paint cleaning

- Cleaning of accumulated dirt in parts warehouses

- Remove rust from ships and the shipping industry

- Prepare metals for coatings

- Deep cleaning in the aeronautical industry

- Cleaning of accumulated food in the food industry

Laser cleaning has been a revolution in effective industrial cleaning, CONTACT our experts and receive advice.

DISCOVER MORE ABOUT LASER CLEANING: