Recondition automotive parts with laser cleaning

Today, laser cleaning has gained quite a lot of popularity in different sectors. It is an innovative technology that represents a revolution in the industrial cleaning sector , both for its performance and for its wide variety of applications. Laser cleaning machines are high quality and versatile equipment. What types of applications can we work with laser cleaning? What advantages do these machines have? We are going to answer some of these typical questions regarding this technology and we are going to focus on a very specific application: laser cleaning in the automotive industry.to recondition parts. This is a very interesting application to reuse parts and components that can have a second use and extend their useful life.

Advantages and works with a laser cleaning equipment

Laser cleaning machines work with a high-quality fiber laser. They are versatile and comfortable equipment to use, with an easy-to-handle laser gun. Some features that convince users of these devices are:

- Few consumables.The cleaning machine allows us to save time and money, it is a faster process than other cleaning methods, we save hours of work. In addition, we avoid using chemicals and other consumables to clean.

- Eco-friendly process.These teams do not generate waste that harms the environment. Depending on what material is cleaned, a small amount of smoke or dust is generated that remains in the environment, easy to vacuum with any ventilation and/or extraction system. In any case, these equipment consume less energy than other laser systems.

- In addition to being able to choose between different laser machine powers , with the same equipment we can clean different types of dirt such as: grease, oil, rust, accumulated food, etc.

- Little maintenance.In general, these devices do not require much maintenance.

Recondition automotive parts with laser cleaning

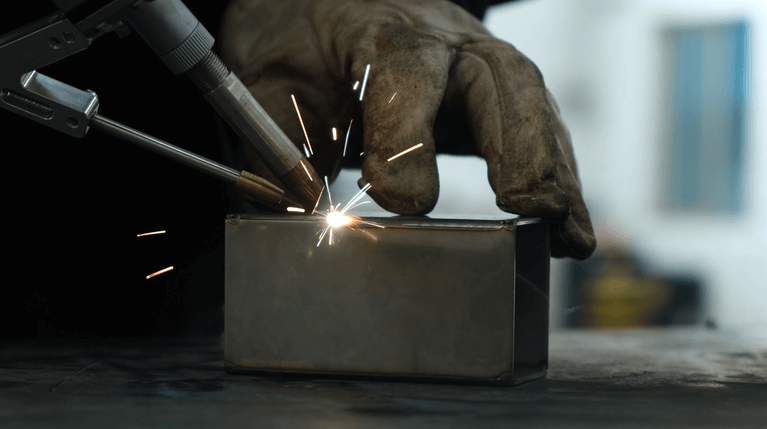

Many parts in the automotive world are very easy to clean with a laser . The fiber laser impinges on the material, causing it to evaporate and removing impurities from a surface . Another great advantage of laser cleaning machines is that the substrate is not damaged, it remains intact.

In this way, some applications for the automotive world are:

- Cleaning of car rims, possibility of removing all kinds of dirt and reconditioning them for new use.

- Removal of coatings to apply new ones . It is possible to remove not very gauzy paints and some coatings to give a new life to some pieces.

- Cleaning of engines and mechanical components. It is very easy to remove accumulated grease and oils from engines and mechanical components with the laser cleaning machine .

- Remove rust from automotive components that have been affected by corrosion. One of the most surprising applications of laser cleaning is precisely the ability to remove rust from different surfaces.

- Cleaning of welds or preparing materials to be welded . A little known application of laser cleaning is to clean welds that have been darkened or to use the laser to remove impurities prior to welding work, thus being able to make higher quality welds.

- Renovation of tools with accumulated dirt.