This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

The laser as a system for cleaning and removing coatings

Summary

Laser cleaning offers an effective solution to the problems of removing coatings applied to different materials.

Laser machines are an innovative technology that presents improvements over other more traditional options.

That is why in this blog we will tell you in detail the advantages of making use of this system that is increasingly taking a position in the current market. It should be noted that this alternative provides an eco-friendly service since, compared to other methods such as sandblasting or pressure washing, no gases are emitted into the atmosphere nor are large amounts of polluting waste produced.

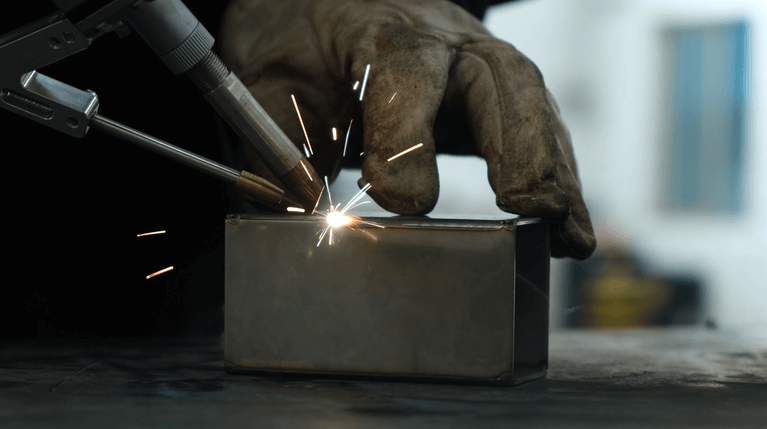

Thanks to laser cleaning machines we can solve problems that we cannot with traditional methods . The biggest difference is found in its non-contact and non-abrasive process, that is, only the laser light touches the material and through the energy, it is heated, which allows the material to be expelled. Thus, the substrate we work with remains intact.

The coatings:

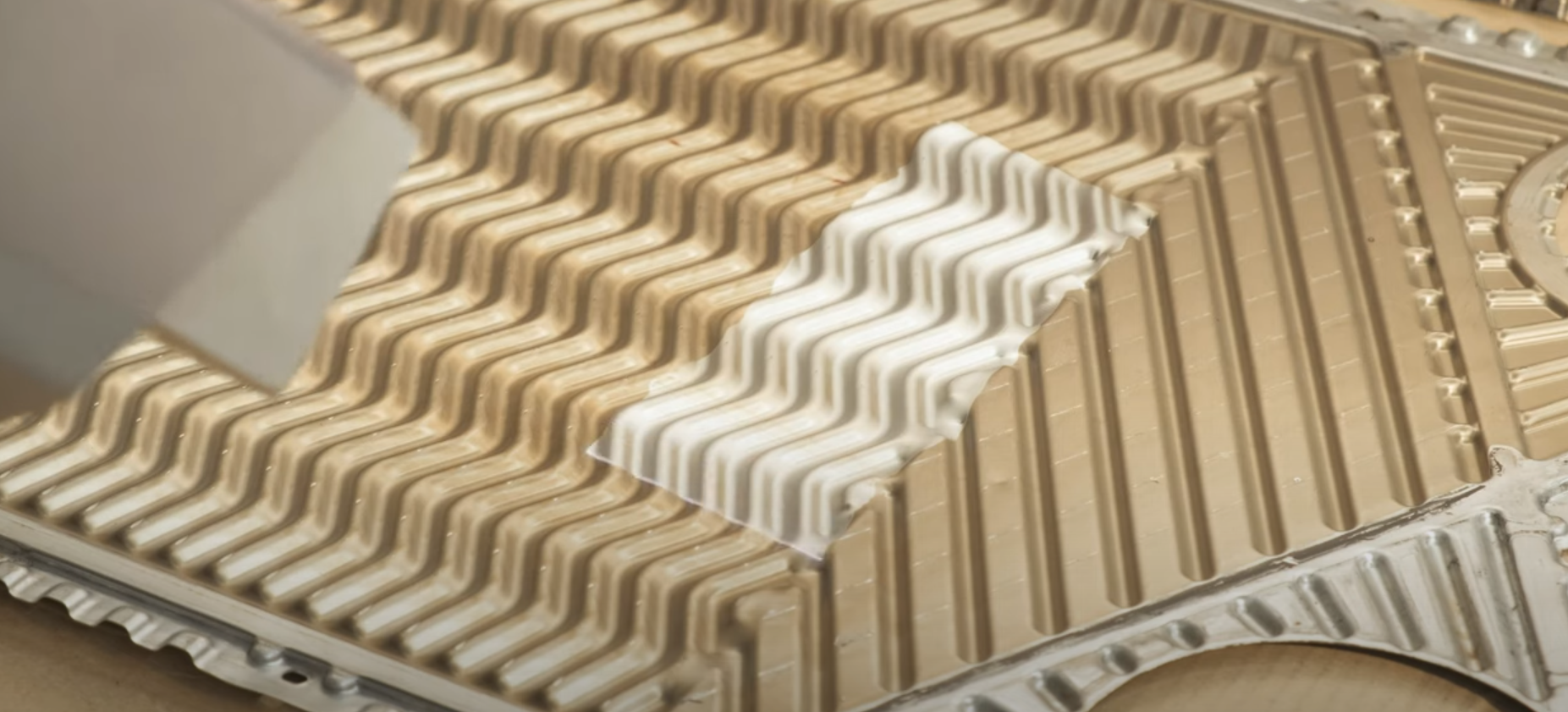

As we have explained before, laser cleaning machines are relatively easy to use and can be used on different materials without damaging the substrate. Coatings being one of the most common types of dirt to clean with a laser . This system allows you to safely remove different types of coatings such as paint, material protectors, among other options. This is just one example of many where laser technology could be successfully applied, depending on the industry. For example we could also clean rust, remove accumulated dirt, clean grease and oils or accumulated food, just to name a few examples.

Laser Ablation:

Laser cleaning is based on a physical reaction called ablation. Each material will have a different level of ablation, so it will allow you to work and clean at more or less power. There are different models of laser machines with different powers, each user can choose the equipment with the laser power that best suits their work. It should also be borne in mind that these laser machines can be configured in power and speed for each specific job, they are very versatile. To successfully and effectively clean a specific material, the energy transferred from the laser should always be above the ablation level of the material in question.

Laser cleaning is the only method that performs a deep cleaning while the other methods only remove part of the dirt. This type of cleaning allows pigments and polymers to be removed while most other cleaning systems only remove pigments but not polymers, laser cleaning, for example, could be a great substitute for sandblasting or other cleaning. systems.

The laser, an effective option

Laser technology has surpassed other methods that have always been used in cleaning coatings or different substances in general due to the speed of the process, how simple it is to apply and the effectiveness it provides. There are many advantages and facilities when working with laser cleaning .

The user can quickly learn how to use the laser equipment with easy training. Other advantages would be:

- No chemicals, which tend to harm the substrate and the environment in the long term

- We eliminated risk factors, such as damage to workers due to different factors such as noise contaminants.

- Versatility with the same equipment. We can perform different types of cleaning with the same machine.

- Less costs due to expenses for consumables or the long life of our machines.

Laser cleaning machines are an excellent option for deep cleaning. On our website LaserComercial.com you can request information to carry out your applications, or if you have any questions about whether or not you could clean a specific material or surface with laser cleaning equipment, contact our experts to answer all your questions.