Is it possible to clean graffiti with laser cleaning?

Summary

In different parts of the country just by raising our heads we can see graffiti on the walls of some houses, in museums, in public places and even monuments or statues in parks or cities. This trend was born in Paris and has spread over the years to different parts of the world. A very controversial topic that is criticized by many and accepted by others. The graffiti are usually done with aerosols, markers, acids or plastic paints and can damage the surface of the walls or facades.

Sometimes graffiti remains for years and years on walls in different places, even some graffiti become very popular for their artistic quality and other reasons and are visited as a tourist spot. Other times, methods will be sought to try to clean graffiti from walls or other surfaces. A little-known option is laser cleaning , capable of removing paints, some aerosols, and coatings from walls and other surfaces.

Alternative methods for graffiti removal:

Today, there are countless graffiti removal products that help reduce its effects and make cleaning up afterward much easier. But each of them has a certain level of effectiveness, with the laser cleaning technique being the simplest and easiest to use.

What are the other techniques to be able to clean graffiti?

– Sandblaster method. It is a way to clean graffiti by projecting baking soda. It requires a high level of preparation on the part of the operator, since it depends on the surface to be applied, a special type of sandblasting is needed. In addition, the operator must carry many security measures.

– The use of paint stripper. It is the most used technique when you want to remove graffiti from surfaces. But many factors have to be taken into account that may not have been taken into account. Starting that the use of chemical pickling can only be carried out by trained people. Divestment is never an activity that everyone can do because the skills required are high. Second, full body protection should always be provided. With all the dangers associated with stripping, every inch of your body needs to be protected and secured.

– Pressure washing. Pressure washing is usually an option to clean this type of paint, but it can cause a lot of discomfort during and after the process. Since all the water used in the process falls to the ground with all the dirt and causes discomfort to the people who attend the area. As it is also necessary to take into account placing various work zone signs so as not to affect the safety of passers-by. Another factor that must be taken into account is fragile or old surfaces, since pressure washing, being a technique that causes erosion on the surface, must be discarded or carried out with great care, since it could cause irreparable damage.

Laser cleaning has also sometimes been presented as an alternative to dry ice .

Advantages of Laser Cleaning:

We have already talked many times about the advantages of laser cleaning machines in different industries. The truth is that it is a technology that is becoming popular for different applications, even so it is still not very popular in cleaning graffiti. There are different factors that will determine if laser cleaning will be the best option to clean coatings or graffiti: the amount of paint, the type of substrate where it is, the power of our laser machine. However, we are going to highlight why it could be a good option for this type of work:

- Laser cleaning does not cause emissions or pollutants.

- Few consumables and very little maintenance.

- They do not require a high level of preparation on the part of the operator.

- Simple use and easy to learn.

- It does not cause damage to the environment , nor to the surroundings, since, as is the case with pressure washing, it does not require a high level of safety or protective equipment.

- The laser equipment uses a fiber laser , which offers us great effectiveness and quality.

- Save time, reduce costs.Thanks to the efficiency of laser cleaning, it allows us to save time and reduce costs in the long term.

- Laser equipment has good controllability, high flexibility, easy implementation, and high precision.

If you want to continue learning more about the advantages that laser cleaning machines offer you, you can see our Blog What are the advantages of laser cleaning? where we go into detail about all the opportunities that acquiring a Laser Cleaning machine would bring you.

Laser Cleaning Machines:

Laser cleaning machines are a new high-tech system for cleaning surfaces. This last alternative is really easy to install, control and implement. They have a versatile system that can be used on many surfaces, cleaning quickly while respecting the environment. The cleaning equipment has a durability of up to 100,000 hours.

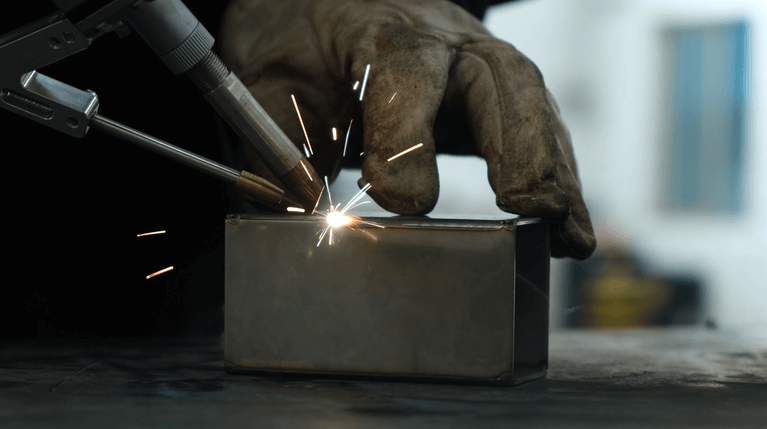

Quickly cleans all types of metals at incredible speed. With this equipment it is possible to remove rust, paint, coatings, dirt accumulated over time, grease . With a simple operation, cleaning can be achieved without chemical reagents or other contaminating media. perfect for cleaning welds, resin, grease, stains, dirt, rust, coating, paint.

It has a design capable of moving around the workspace with wheels that allow the machine to be moved and placed where it is required, while remaining a smaller and more compact machine than other machines.

Other apps:

Laser machines are not only feasible for the use of urban graffiti cleaning, they can also be useful for many types of cleaning. Since, as we have seen before, laser cleaning machines have a very versatile system that allows them to carry out a variety of applications. Next, we will tell you some examples of which laser cleaning machines would demonstrate their effectiveness and speed in the face of some problems, such as the following:

- RUST AND CORROSION REMOVAL.They can be used to remove and remove rust from small machines or materials kept outdoors for a long time.

- CLEANING OF PAINTS . It allows to remove paint of all kinds in steel structures.

- RESTORATION.In the restoration process, laser cleaning has been used with satisfactory results in, for example, the conservation of stones to remove scale or even the reconditioning of parts from different industries.

- WELDING CLEANING . Preparing the material for weld processing in the steel industry is vital. Laser cleaning systems can be integrated into production lines.