Laser cleaning in the aeronautical industry

Summary

Aeronautics is a discipline dedicated to the training, design and manufacture of mechanical devices capable of ascending in flight , as well as technologies capable of controlling aircraft. The aeronautics sector is an industry of great impact and purchasing and economic value at a global level. Because it is responsible for the design, manufacture, marketing and maintenance of different types of aircraft: commercial aviation, executive aviation, remotely piloted vehicles, military aviation, helicopters, etc. Engineers in the aeronautical sector are responsible for the design of all kinds of devices that can fly . In the same way, they apply science and technology for their research, design, manufacture and maintenance.

In this blog we will discover the avantages of laser cleaning in the aeronautic industry.

Laser cleaning in aeronautics

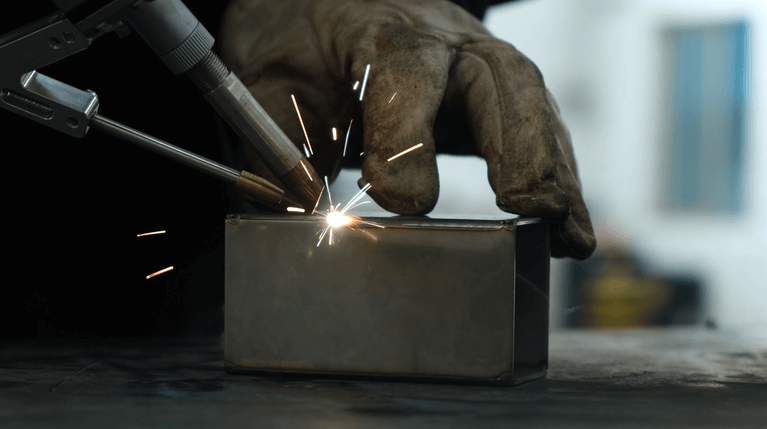

Before carrying out according to what works in these industries, the parts and components must be completely deoxidized so that they work well. In this case, laser cleaning can be very precise and useful for cleaning materials in the aeronautical world, either to clean the final product or to clean materials to be worked on later. Laser cleaning machines can remove lacquer without damaging or altering the resistance of the substrate in the aeronautical sector. In addition, it can clean numerous metallic platforms, basic components and parts with some type of dirt or corrosion.

Usual applications:

- Cleaning residue and paint from welding

- The treatment of aluminum components for the application of insulating layers

- Cleaning of turbine blades.

- Removing paint for repair purposes

- Production of contact surfaces for electrical conductivity

- Spot bonding, pretreatment for fixing fasteners

- The paint pretreatment of the latest generation titanium components

- Manual and automated cleaning of metal molds

- Surface treatment

The operating costs of laser systems are significantly lower than those of conventional processes. Although the equipment is sometimes more expensive than other systems, it pays for itself faster, since it has almost no maintenance costs and has a long useful life. The process is comfortable compared to other processes.In addition, they are configurable equipment for each job. Laser cleaning technology is commonly used in the maintenance of parts and machinery in different sectors. With a laser cleaning machine you can quickly and effectively remove rust and contaminants. In addition, the piece is not damaged, the substrate remains intact. It is a safe process for the user, which has good results.

Benefits of laser cleaning machines

Laser cleaning machines provide us with a series of benefits, starting by saying that they are very versatile and have incredible capabilities. They are capable of removing different kinds of unwanted substances effectively and easily to leave the substrate clean and treated. The laser cleaning machine is also very manoeuvrable, it can also be configured to clean as required. Laser cleaning is useful for removing paint, grease, oils, coatings, rust, mold, corrosion, among others.

Laser cleaning is highly effective and has many advantages over other processes such as sandblasting or the use of chemicals. It is an eco-friendly and safe process for the user of the laser cleaning machine . By cleaning rust from our materials we can extend the useful life of the machines, structures and parts that we clean, since we will do better maintenance and care.

All this can be worked on different materials without being affected, laser cleaning does not damage the substrate. LASERCOMERCIAL ‘s laser machine is manageable and easy to configure and operate. This also means that laser equipment is very efficient and allows cleaning different types of dirt such as paint, coatings, accumulated grease, dirt, corrosion, among others. Applicable to many industries and sectors such as aeronautics, aerospace, automobiles, parts reconditioning, restaurants or the food industry. And finally, it must be taken into account that they contain a high-quality fiber laser, with a long useful life. They are robust equipment with a manageable laser gun that allows you to work in a comfortable and in a practical way.

More applications:

LaserComercial has a constant commitment to its customers to offer them the best laser machines with high quality and efficiency. Laser cleaning machines are no exception, as we have already stressed before, they are very versatile, which allows them to be used for different types of applications on different materials or surfaces. These types of emerging technologies are increasingly occupying more space in the market because they help speed up processes in the different types of industries where they work and because of the low price of their long-term operations due to their long useful life. To all this due to the large amount of materials that can be cleaned by the laser machines, the most common applications are to remove rust and paint or grease and accumulated dirt.