Laser cleaning of metal strips from wine barrels

Summary

A wine barrel is made of two components: wooden staves and steel rings, usually called hoops . The steel straps are the components that surround the barrel, ensuring the maintenance of the staves between them and protecting them during movement. In other words, these metal straps are rings placed in pairs that hold the staves together and hold them tightly together, thus preventing leaks at the joints of the staves. Depending on the location, they are named differently :

Head: They are the external strips. They hold the staves by their head and collaborate to fix the tops or bottoms to the staves from above. It is the edge that protrudes from the barrel. Argallo: They are located below the Testa strips. They allow the tops or bottoms to be kept attached to the staves in the cavity and, together with the external strap, collaborate to keep the ends of the staves together and airtight. Neck: In large barrels another strip is added on the belly. Barrigal: It is located above the belly of the barrel. Keeping the staves together so that the shape of the barrel is not lost and there are no leaks.

Over time, these barrels and their straps can rust, collect dirt, and lose effectiveness. How can we restore these strips to extend the useful life of the barrels? How can we clean wine barrels? In this article, LaserComercial will demonstrate the effectiveness of laser cleaning machine processes when applied to this type of surface.

Application of steel strips with Laser Cleaning:

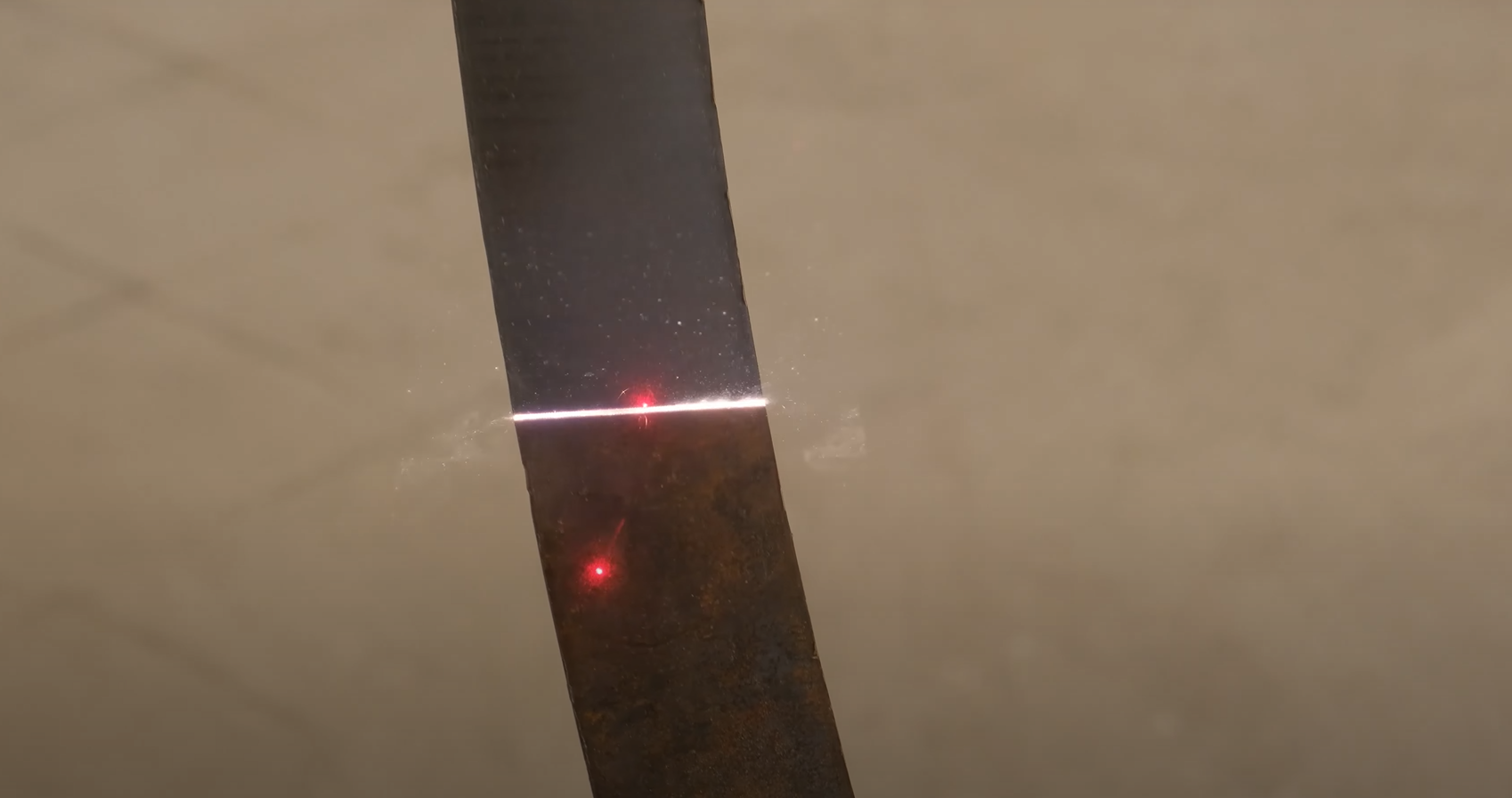

These barrels are usually in storage for many years, which can cause damage due to corrosion in this type of component. In this case, laser technology has been used to remove rust from metal strips from old wine barrels in poor condition . Although strapping is often made of stainless steel and compared to other commercial metals and alloys, it is more resistant to corrosion and will not rust in normal environments. This type of metal contains chromium and, when exposed to oxygen, forms a thin, invisible layer called chromium oxide. It is also thanks to the laser cleaning system that we can remove this type of impurities.

Normally the useful life of a wine barrel can reach more than 40 years, which makes it easy for steel strips to be affected over the years due to time elapsed or other environmental factors. That is why LaserComercial offers you the best in laser cleaning technology to be able to remove all the impurities and oxides until leaving a completely clean surface .

Thanks to laser cleaning we can restore and recondition giving a new life to parts, machines, etc. Apart from rust, laser cleaning machines are also responsible for removing dirt or all kinds of impurities from the surface where it is being applied. Laser cleaning is highly ecological since it avoids the use of chemicals in deep cleaning and this means that polluting residues are not produced for the environment, thus also avoiding possible damage to the substrate.

Demonstration of laser cleaning of steel strip:

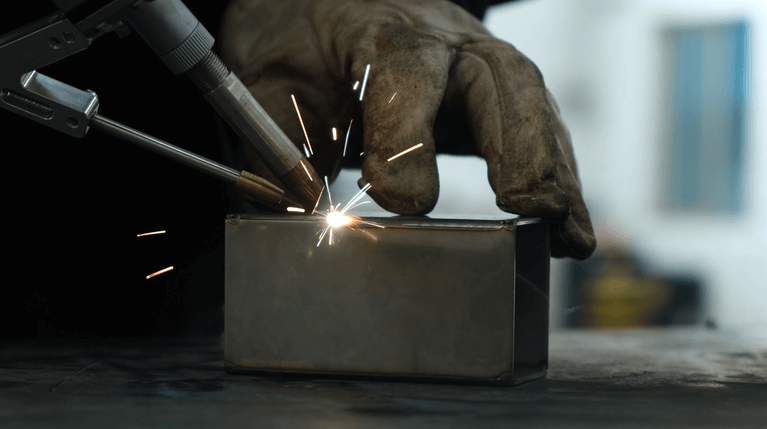

We have a video on our LaserComercial YouTube channel where we have tested the functionality of laser cleaning machines to remove rust and impurities from the steel strips of a wine barrel. The laser is controlled via a touch screen. Through the menu, the parameters of the laser output can be configured before working. Once the parameters have been edited and with the appropriate security measures and a safe environment, the user uses the laser gun to clean what would be in this case the steel strips .

This demonstrates the versatility of laser cleaning machines and their use on different materials in different industries. The number of applications that laser cleaning equipment has is very wide and many times it allows us to clean surfaces that we did not even think could be applied . Many times our clients surprise us with the use they want to give the laser equipment , it is just a matter of choosing the right power that can vary according to different factors such as the amount of impurities you want to remove or the material where you want to apply it.

Another question that may arise is knowing which laser cleaning machine you have to buy. In order to help you, we have published an article entitled, ” Choosing the right laser cleaning equipment“ , where we explain in detail each of the benefits of the three types of laser cleaning machines , classified by power. We have 100W, 200W and 500W machines. It is noteworthy that, being configurable equipment, a high power machine could work as a lower power one with the appropriate configuration.

If you have any questions, you can review our articles in the laser cleaning section to learn more about its different benefits or you can contact us, so you will receive individual advice from professional salespeople in the laser cleaning sector.

Other applications of laser cleaning:

In this blog we have specifically commented on the cleaning of impurities and rust from the steel strips of the wine barrels. But laser cleaning has many more applications . But we already know that our laser machines are very versatile due to the number of materials or surfaces where we can apply this system . These are other applications where we could use laser cleaning :

- Resin

- Paint on walls or metal surfaces

- Accumulated dirt on machines or similar

- Coatings, remove them to apply new ones

- Grease and stains