LC WELD SMART vs LC WELD PRO

Summary:

The LC Lasers laser welding range has two manual laser welding equipment: LC WELD PRO and LC WELD SMART. What are the differences between them? Does the quality of the weld change?

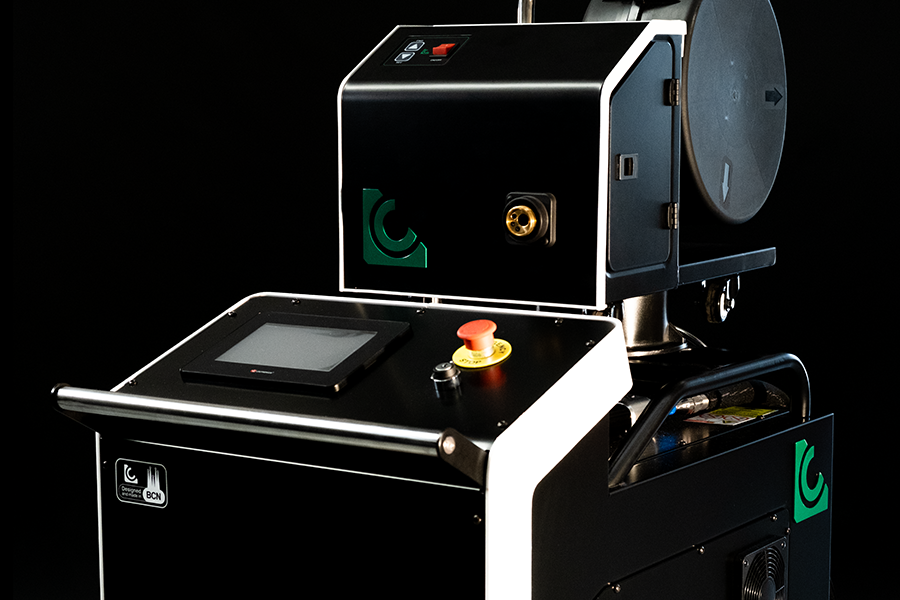

In this article we will focus on the LC-WELD SMART, the smaller and simpler version of the LC-WELD welding equipment, but maintains the same quality and reliability. This machine is designed for light and medium welding applications.

Features of the LC-WELD SMART

• Feeder: Removable feeder without the need for a new external system. Improved drag quality with self-made electronic board and original design.

• 40% efficiency: Equipment with a state-of-the-art laser generator with an improved efficiency of 40%.

• Metal welding versatility: LC WELD SMART allows us to work different metals with the same machine. We can perform welding on carbon steel, stainless steel, aluminum, galvanized steel, titanium and special alloys.

• Small size: The LC WELD SMART equipment is the smallest of the LC WELD laser welding range. A more maneuverable and lighter equipment, but with the same quality.

• CW Laser Quality designed for welding: We use a continuous wave (CW) laser that gives better and higher quality results compared to other lasers such as quasi-continuous (QCW). Greater speed, less material deformation and more depth. Laser designed and prepared specifically for laser welding.

• Better gear factor: Gun with better gear factor for welding such as aluminum.

• Welding quality and savings: LC WELD SMART offers us the possibility of working on high-quality welds, very fine welds, complete penetration and without excess addition. We save time on polishing and expenses. With the laser, firm and deep welds are obtained without overheating the material, with much less deformation of the materials, especially those with low thickness.

Differences and similarities between the LC-WELD PRO and the LC-WELD SMART

Differences and similarities between the LC-WELD PRO and the LC-WELD SMART

Similarities:

- Laser gun: Both teams have the same laser welding gun designed and manufactured by LC. A welding system that allows us to work efficiently and versatilely, with the most advanced galvanometric motors. This gun also has a better duty factor for complex welds such as aluminum.

- Feeder size: Both machines have the same feeder.

Differences:

- Cost control: LC-WELD PRO has a complex statistics system to calculate work costs in different aspects. While the LC-WELD SMART does not include this functionality.

- Equipment size: LC-WELD PRO measures 970x450x1100mm while the LC-WELD SMART measures 900x500x870mm.

- Control of users and jobs: In the LC-WELD PRO we can create different levels of users to assign the level of access they have or facilitate the work so that each user has saved parameters. In the same way, the PRO team allows us to configure pending jobs, assign them to groups of users and have exhaustive control of the time spent and costs on each job.

- Screen: The screen of the LC-WELD SMART is 7”, while that of the LC-WELD PRO has a 10” screen.

- Tutorials: The LC-WELD PRO software has the possibility of resolving doubts from the workplace, with integrated video tutorials, while LC-WELD SMART does not.

- Cooling: LC-WELD SMART has the Active Air Cooling system, through a gas circuit, while the LC-WELD PRO is cooled through water.