This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

What materials are suitable for laser marking?

Summary:

Whether you work in the personalization industry or run another business that requires unique markings on different surfaces and materials, you’ve probably wondered what laser marking technology is and how it can help your business.

In this article we explain what this marking system is about, so we can start by saying that fiber laser machines have an unlimited number of applications and are extremely versatile, allowing the customization of many items. Not forgetting that these lasers are capable of marking a wide variety of materials with high-quality sharpness.

It is becoming very common for many businesses to choose laser technology as an alternative for personalization techniques due to its wide range of possibilities. Laser marking machines are designed for laser marking and engraving, but can also be used for cutting, depending on material and thickness.

If you wish to contact us, you can do so through our contact form , in this way, a technician specialized in laser marking will contact you to answer all your questions.

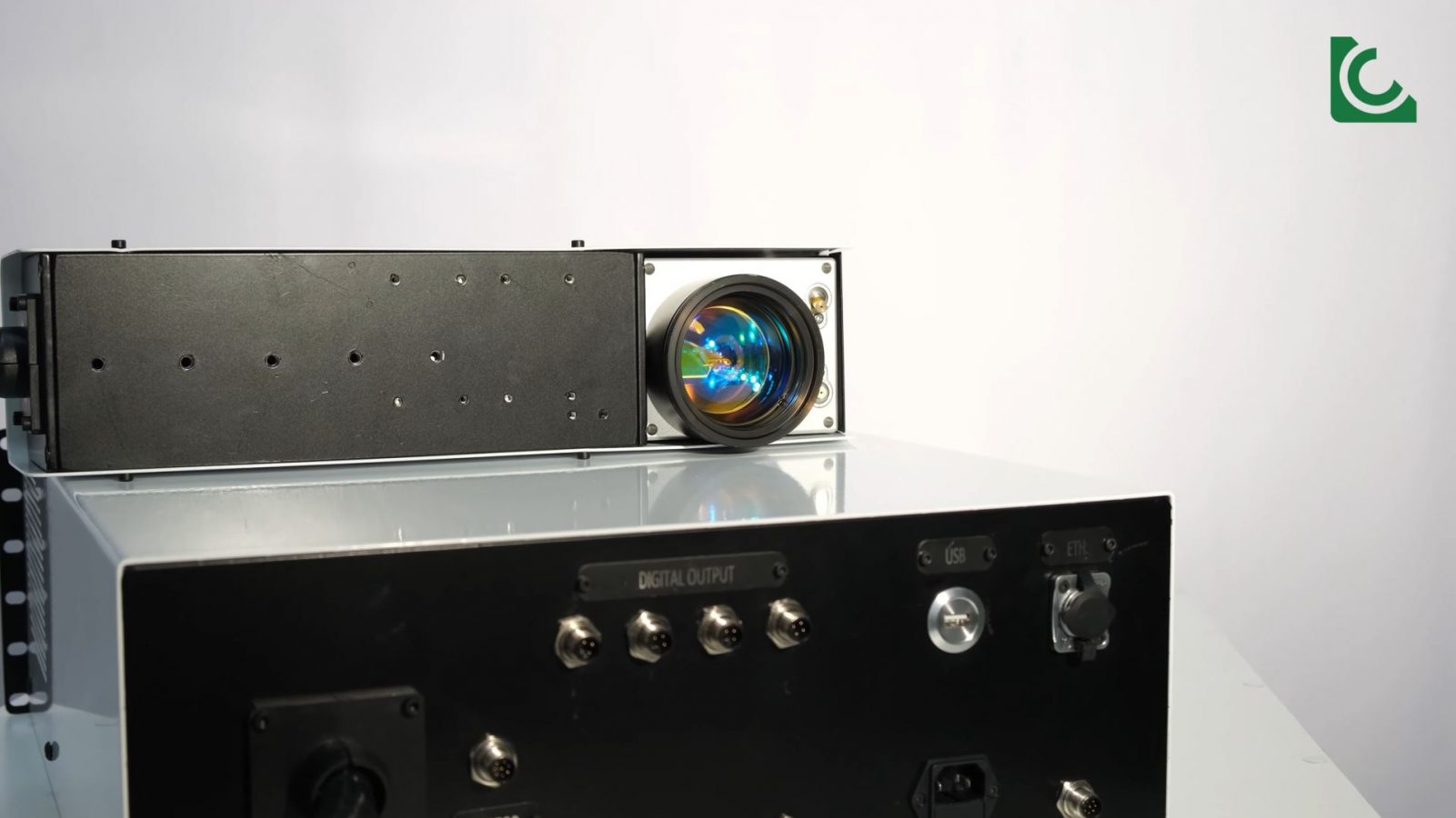

<<LC-FIBER>> laser marking machines

Both Co2 and fiber laser equipment have a mirror system, the so-called galvo head, which guides the laser precisely towards the surface to be marked or engraved. This system uses two mirrors that rotate at high speed, away from the material, and quickly reach the desired position.

LaserComercial has a compact device for laser marking and engraving that can also be used for cutting, depending on the material and thickness. The fiber laser is suitable for marking materials such as stainless steel, carbon steel, aluminum, copper, acrylic paint, blue glass, PVC … Some of its advantages would be:

- Permanent applications. The laser marking is permanent and cannot be easily changed, and these markings are of high quality.

- Reduction of environmental pollution.We avoid using glues and inks to mark and implement designs and codes. These products harm the health of the environment.

- Easy operation.The laser marking equipment has a Plug and Play system and EzCad Laser Software that is easy to work with and learn to use.

- High speed.For some applications, the speed at which this equipment can reach is very interesting. It can reach a working speed of up to 8000 mm/s.

- Own production and design. LaserComercial marking machines are designed and produced in-house, every detail is carefully thought out so that it works from the first moment.

What types of materials can we laser mark or engrave?

Laser marking enables fast, high-quality finishing of intricate details. They are compact equipment with everything necessary integrated to implement designs of all kinds: logos, drawings, barcodes, QR codes, data matrix, numbers, inscriptions, among many other options.

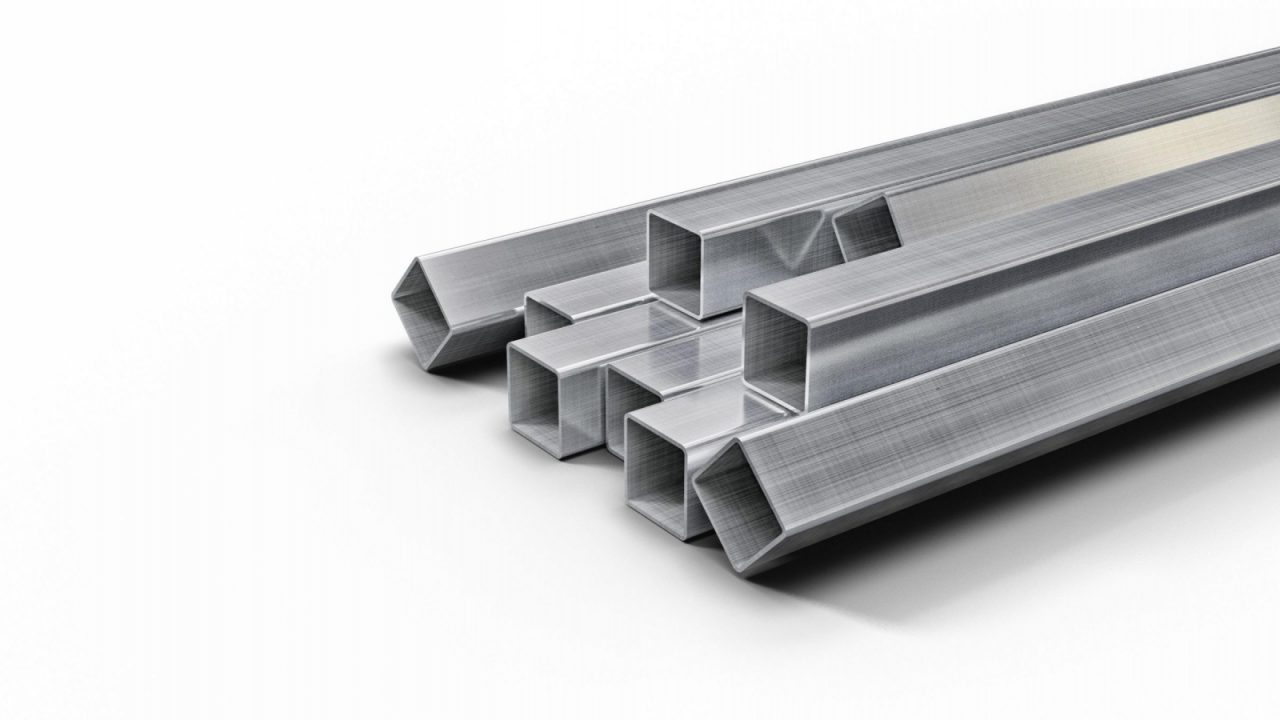

In the same way, they can be applied to a wide range of metallic materials such as steel, bronze, copper, silver, gold, polycarbonates, plastics, ceramics, some resins, PVC and many more.

Next, we will explain some of these materials in more detail:

- Aluminium: one of the most common materials for laser marking, used in many sectors. If the laser intensity is low, the foil mark will be white. The higher the intensity of the laser, the darker the mark will be.

- Plastics – Fiber lasers are also used to mark and etch plastics and polymers . The most common method of marking plastics is color change. Laser energy is used to change the molecular structure of the component, and using a laser device, marking is done by changing color.

- Stainless Steel – Along with aluminum, stainless steel is often used for engraving and marking with fiber lasers due to its greater efficiency. It can be used in almost all industrial sectors. It can be used regardless of the size of the piece, as it can mark and engrave both small items and large letters.

- Gold and silver: Marking silver and gold can be difficult, but it is possible with a fiber laser. These metals are very soft and require the application of very specific parameters.

How is marking and engraving different?

Pulsed fiber lasers are known to be very versatile and are used especially for laser marking, which is one of the most popular applications.The difference between laser marking and laser engraving is mainly about the end result. Although they appear very similar at first glance, laser marking is a superficial impression, while laser engraving gives a deeper impression.

Therefore, laser marking allows designs and codes to be placed with little or no penetration. When traced with a finger, the surface appears solid. Laser marking is visible to the eye, but cannot be touched.

Instead, laser engraving allows the desired design to sit deeper into the surface. In this case, when traced with the finger, the laser engraving is visible to both the eye and the sense of touch, and the markings are clearly visible.