Ecological Advantages of Laser Cleaning

Laser cleaning is an innovative, eco-friendly method used to remove dirt, rust, paint, and other types of contaminants from different surfaces without physical contact. This method is highly efficient, precise and minimizes damage to the original surface. From an ecological perspective, laser cleaning offers several advantages over traditional cleaning methods that often use harsh chemicals or generate secondary waste that can be harmful to the environment.

No chemicals: Unlike conventional methods that may require solvents and other chemicals, laser cleaning does not require these materials, reducing the emission of VOCs (Volatile Organic Compounds) and other contaminants.

Waste Reduction: By generating no secondary waste apart from the removed material, which can often be collected and recycled, laser cleaning contributes to less waste generation.

Saving water: Traditional cleaning methods, such as pressure cleaning, can consume large amounts of water. Laser cleaning, on the other hand, does not require water, which helps conserve this vital resource.

Energy Efficiencies: Although laser cleaning requires electrical energy, technological advances continue to improve its energy efficiency. Additionally, the precision and speed of the process can result in lower energy consumption compared to more labor-intensive or less efficient techniques.

Safety and Health: By eliminating the use of hazardous chemicals and reducing the generation of dust and other airborne contaminants, laser cleaning improves working conditions and reduces the risk of health problems associated with more traditional cleaning techniques.

.

Laser Cleaning with Clean-P

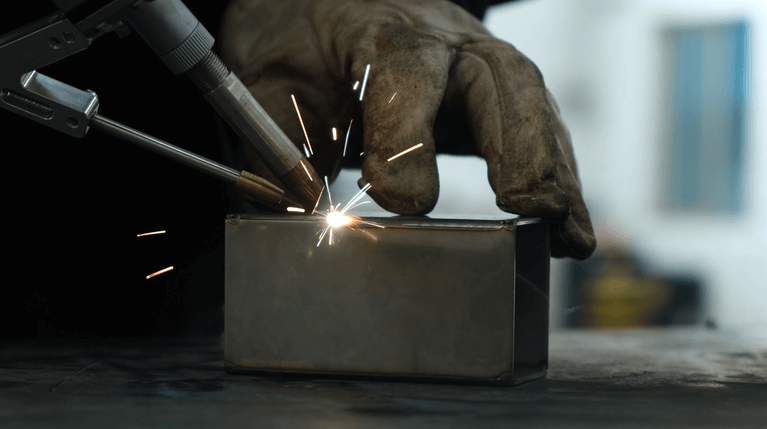

In this video you can see an example of cleaning with the LC-Clean P laser cleaning machine. The LC-Clean P allows you to achieve perfect results. It is a state-of-the-art equipment that uses the laser as a stripping system to extract impurities, leaving the substrate intact.

It offers us a wide range of application possibilities in different industries or sectors. Being versatile equipment allows us to remove rust, paint, coatings, dirt accumulated over time, grease... These equipment allow us to carry out contactless and very precise cleaning.

Unlike other alternative systems, laser cleaning can work without any abrasives or contaminants.

Laser cleaning does not require a high level of specialization on the part of the operator. This laser machine has an integrated control that allows you to set the speed, the laser output shape or the beam width. In this way, it is possible to adapt the machine to each job to be carried out, in addition to being able to save parameters for future occasions in a very simple way.

At LC Lasers we have different models classified by power. The choice between one power or another will depend on different factors, including the type of work to be done.

Ecological Applications

Laser cleaning applications are diverse and can include the restoration of historical monuments, cleaning industrial equipment, preparing surfaces for paint or coatings, and removing manufacturing waste, among others. Its ability to clean effectively without harming the underlying surface or the environment makes it particularly valuable in sectors where conservation and sustainability are priorities.

In summary, laser cleaning is a promising technology for environmental sustainability, offering a cleaner, safer or more efficient alternative to traditional cleaning methods. Its increasing adoption can play an important role in reducing the environmental impact of cleaning activities in various sectors.