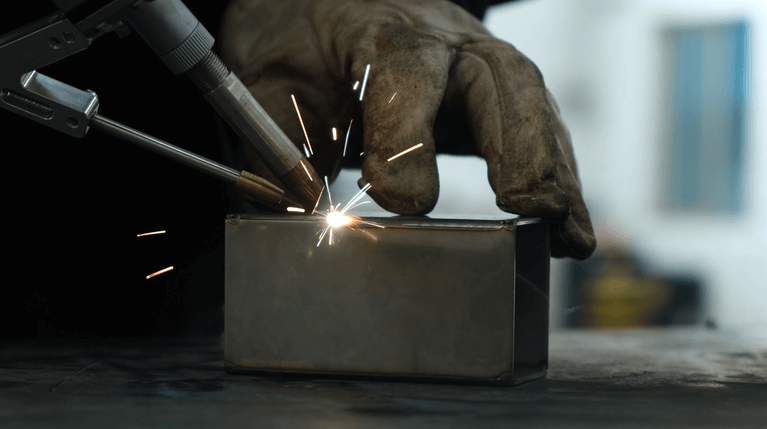

How to Perform Laser Rust Cleaning

Total Transformation with Laser Cleaning: Technology for Rust-Free Surfaces

Laser cleaning is revolutionizing the way industries tackle rust on metal surfaces and other materials. At LC LASERS, we specialize in the sale of advanced laser cleaning machines capable of transforming rusted surfaces into flawless finishes without damaging the base material or requiring chemical agents. This innovative method is ideal for many sectors, providing a safe, efficient, and environmentally friendly solution for rust removal and surface restoration.

Laser Cleaning and Its Advantages

Our laser cleaning machines remove rust and other contaminants using a concentrated light beam that operates without direct contact, preventing material wear and avoiding the risks associated with conventional methods. Additionally, these machines produce no hazardous waste, making the process safer and more environmentally friendly.

Key advantages of laser cleaning include speed, precision, and the potential for automation, which reduces time and costs. The machines can be configured according to the type and thickness of rust, ensuring a tailored treatment for each material without risk to the underlying surface.

Preparation and Operation of Our Machines

For effective treatment, we recommend an initial cleaning of surfaces to remove any grease or dirt, along with an inspection to assess the level of rust. Calibrating the machine is essential, allowing the light beam to be adjusted according to the degree of oxidation and the type of material, ensuring safe and effective results.

During the process, the machine directs the laser beam over the affected area, where the energy is absorbed and disintegrates the rust. The generated residues are minimal and are easily removed by an integrated vacuum system in our machines, leaving the surface completely clean.

Efficiency and Safety in Laser Cleaning Use

To ensure safe operation, we recommend that operators follow our safety guidelines and wear personal protective equipment, such as safety glasses. At LC LASERS, we also provide training for optimal machine handling and offer technical support and maintenance kits to maximize equipment lifespan.

Laser cleaning not only renews surfaces but also serves as an essential tool to maintain material quality and durability. With our state-of-the-art machines, you can transform your cleaning processes efficiently, safely, and in an eco-friendly manner.