Cutting-edge technology with an award.

LC Lasers was the winner of the 6th Business Development Initiatives Award from Gest!

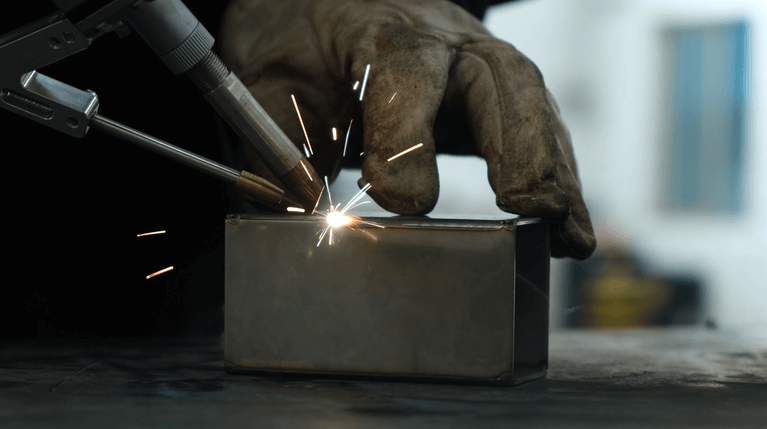

The laser technology has a long history across various industries. For years, it has been applied in different fields and for different purposes: for precision work, for cutting metal and engraving, for marking on various surfaces. Even in medicine.

Focusing on the industrial world, although it has existed for many years, new equipment has recently emerged that harnesses laser technology to push production and industrial excellence further. The purposes are as varied as the possibilities offered by lasers, making it possible for many companies to advance the technological innovation of their activities and achieve better results efficiently.

The industrial fabric of Central Catalonia has become strong and has grown in recent years. Among the new projects that have emerged is LC Lasers, a company from Sallent that won the 6th edition of the Business Development Initiatives Award presented by Gest! The Sallent-based company exports laser machinery throughout Europe and focuses on manufacturing laser solutions for welding, cleaning, and marking.

Within its range, it offers both manual equipment and semi-automatic applications. Additionally, it has a significant range of products for safe operation with laser equipment for industrial applications. Having numerous partnerships in countries such as Italy, France, and Portugal, among others, allows them to be present in different European markets. Distribution agreements are essential for the growth of companies.

I+D

The key to success is a strong investment in R&D, which gives the company the opportunity to focus on and enhance laser welding, an application that was largely unknown years ago, despite its great potential. LC Lasers were pioneers in the European field by offering a laser welding product manufactured in Europe in terms of most components and tailored to the needs of customers. Along these lines, a laser welding system with completely new and original software has been developed, with remote connection capabilities, high statistical control, and specifically designed for tasks with this type of welding.

If we talk about laser cleaning, it is an opportunity to work with a machine that could replace technologies such as sandblasting or dry ice cleaning. It means leveraging laser technology to be much more efficient and to opt for more eco-friendly machinery, as laser cleaning generates far fewer residues.

Both in cleaning and laser welding, over time, more traditional equipment can be replaced, such as the aforementioned cleaning techniques or, in the case of laser welding, TIG or MIG welding machines. While it is true that for some welding tasks, other traditional equipment is better, many companies see it as ideal to complement laser welding with TIG or MIG welding. In this case, they can achieve a diversification of tasks without losing quality. Additionally, these laser systems often require fewer consumables, which allows companies to reduce costs.

Potential in the Bages region

It is worth highlighting that laser machine production in the Bages region is strong. In the same region, we find another leading company in the sector: Macsa ID, focused on manufacturing global solutions for coding, industrial laser marking, and traceability. It is noteworthy that two companies from Bages have made such progress in the laser world, offering quality solutions leveraging this technology.

Efforts should be focused on designing and manufacturing a product with most components produced closer to avoid dependence on companies located far from Catalonia. While it is true that, for components such as the laser source, there are very few producers worldwide, most of them centered in China, the rest of the components can be manufactured closer. Challenges should be set to become a benchmark in European laser welding equipment production with presence throughout the European continent.

The different advantages of laser technology allow companies like LC Lasers to offer solutions for very diverse industrial sectors. It is about offering products that allow leveraging all the benefits that this technology offers and, in addition, being able to take advantage of its momentum to reach further.

The sectors addressed by LC are very diverse. Some examples could be: automotive, retail, metal carpentry, aeronautics, transportation, industrial sheet metalwork, nautical, industrial production, and even public institutions.

Challenges

Producers of laser machinery have faced several challenges in recent times. We would highlight: developing new lasers and equipment with the highest possible efficiency, as some equipment requires a lot of cooling and, with a more efficient laser, equipment that allows working with less energy can be achieved. Cooling, in the case of laser welding, also directly affects the size of the equipment, a factor that could be decisive for some customers. This second challenge, reducing the size of the equipment, can be addressed by developing proprietary cooling systems.

In the same vein, a notable challenge is achieving more equipment diversification, for example, in laser cleaning, to achieve more diversified applications. Similarly, another challenge for the sector is providing security around laser technology. Often, lasers can be perceived as a distant and unknown technology and, even, unsafe. It is an important task of the sector to make known the safety measures required to work properly with this type of equipment, in addition to offering real security solutions. It is about creating knowledge around laser technology and access to being able to work safely. On this aspect, the advantages of laser equipment in the industrial sector must be made known, as we are still not aware of all that this technology can bring to our industry.

With these challenges ahead, but also with their numerous and evident advantages, laser technology is a great opportunity for companies to leverage it to improve efficiency, production, and final results.

LC Lasers was the winner of the 6th Business Development Initiatives Award from Gest!