Laser cleaning on navigation components

Laser cleaning on navigation

Nautical restoration takes a step towards the future thanks to innovative laser cleaning technology. MotorNautic, a prominent company in the sector, shows us how they harness the power of lasers to restore shine to deteriorated nautical components.🛳

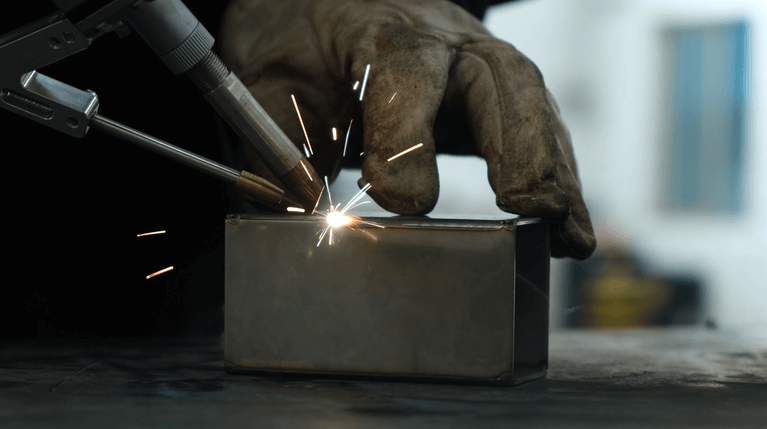

With the help of LC-CLEAN P from LC Lasers, an advanced laser cleaning equipment designed for industrial applications, MotorNautic efficiently and precisely removes rust, dirt, and other contaminants affecting boat parts. Engines, other mechanical components, rudders, and propellers can undergo complete and satisfactory restoration thanks to laser technology.

LC-CLEAN is a versatile and easy-to-use tool, perfect for the demanding nautical environment. Its ability to remove paints, coatings, and accumulated residues without damaging the underlying surfaces makes it an indispensable solution for boat restoration.

Laser cleaning on navigation components is an advanced technique used to keep critical components in optimal condition. These parts, including navigation systems, sensors, instruments, and other devices, are often exposed to severe environmental conditions such as moisture, corrosion, and contamination, which can affect their performance and accuracy.

Some applications of laser cleaning on navigation components include:

- Rust and corrosion removal: The laser beam can effectively remove rust and corrosion from metal surfaces without damaging the underlying material, helping to restore component functionality.

- Lens and optics cleaning: Lenses and optical systems in navigation devices require meticulous cleaning to maintain their clarity and precision. Laser cleaning can safely remove dirt, dust, and other contaminants without scratching or damaging the surfaces.

- Contaminant removal: Laser cleaning can remove oil, grease, combustion residues, and other contaminants from electronic and mechanical components, helping to prevent failures and maintain the accuracy of navigation systems.

- Surface preparation: Before applying protective coatings or adhesives, it's important for surfaces to be clean and free of contaminants. Laser cleaning provides efficient and precise surface preparation to ensure optimal material adhesion.

- Identification and marking restoration: In some cases, laser cleaning can also be used to restore identification marks, serial numbers, or other identifying information on navigation parts.

Laser cleaning offers several advantages, such as precision, efficiency, and the ability to clean hard-to-reach areas. However, it's important to note that laser cleaning requires specialized equipment and trained personnel for safe and effective use. Additionally, it's essential to adhere to safety and environmental regulations when using this technology. Overall, laser cleaning is a valuable tool for keeping navigation parts in optimal working condition and prolonging their lifespan.