The Operation of Laser Marking

LASER MARKING

Laser marking has become an essential technology across various industrial sectors, offering solutions with high precision and efficiency. At LC LASERS, we specialize in providing advanced equipment that enables permanent marking with exceptional quality and speed.

Laser Marking Technology

Our laser marking equipment uses a fiber optic beam that lightly impacts the surface of the material, removing a minimal amount to create the desired mark. This technique ensures sharp and detailed results, accommodating a wide variety of materials, including:

- Metals: stainless steel, aluminum, galvanized steel, carbon steel.

- Plastics: hard plastics such as ABS and PVC.

- Others: glass and various surfaces.

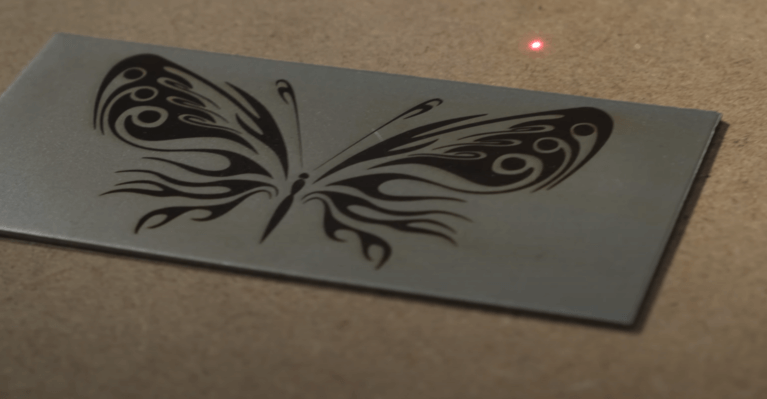

The versatility of our equipment allows for adjustments to parameters such as laser power and speed, achieving different shades and depths in the markings to meet the specific needs of each project.

Advantages of Laser Marking

Choosing laser marking with LC LASERS offers numerous benefits:

- Marking Speed: Capable of reaching speeds of up to 8000 mm/s, optimizing production times.

- Versatility and Efficiency: Adaptable to various materials and applications, ensuring consistent results.

- Eco-Friendly: A clean process that eliminates the need for inks or chemicals, contributing to environmental sustainability.

- Reduced Maintenance: Compact, easy-to-use equipment designed to minimize maintenance needs.

- Ease of Use: Intuitive systems that simplify operation, even for users with no prior experience

Applications of Laser Marking

Laser marking has a wide range of applications across multiple industries. Some of the most notable include:

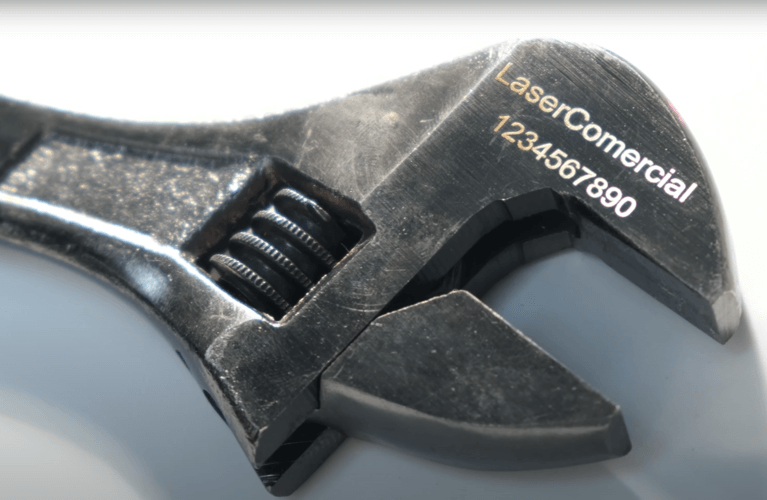

- Identification and Traceability: Marking codes, serial numbers, expiration dates, and data matrix codes on products and components.

- Product Personalization: Engraving logos, custom designs, and text on promotional items, jewelry, and electronic devices.

- Medical Industry: Marking instruments and medical equipment, ensuring durability and readability of information.

- Automotive and Aerospace: Identification of critical parts and components, guaranteeing traceability and compliance with regulations.

At LC LASERS, we are committed to providing laser marking solutions tailored to the specific needs of each client, supported by cutting-edge technology and a team of professionals dedicated to delivering the best service.

For more information about our products and services, visit our laser marking page, LC Lasers.