The Importance of Quality Welding in the Industry

In the industrial world, welding is a fundamental process that connects structures, ensures safety, and enables the fabrication of essential components in sectors as diverse as construction, automotive, and energy. At LC LASERS, we understand that quality welding is not just a necessity but a commitment to excellence and safety.

Why is Quality Welding Crucial?

-

Structural Safety: Poorly executed welding can compromise the integrity of a structure, posing risks to people and operations. Quality welding ensures stability and long-term durability.

-

Cost Reduction: Repairs, failures, or frequent maintenance are expensive and can halt production. With properly executed welding from the start, costs associated with errors or defects are minimized.

-

Compliance with Standards: In many industries, welding must meet strict quality standards. Defective welding could lead to legal penalties or product rejection.

-

Aesthetics and Precision: Besides functionality, a flawless finish is sometimes required, especially for visible components.

What We Offer at LC LASERS

At LC LASERS, we specialize in providing high-quality welding that meets the most demanding industrial standards. Here’s what sets us apart:

-

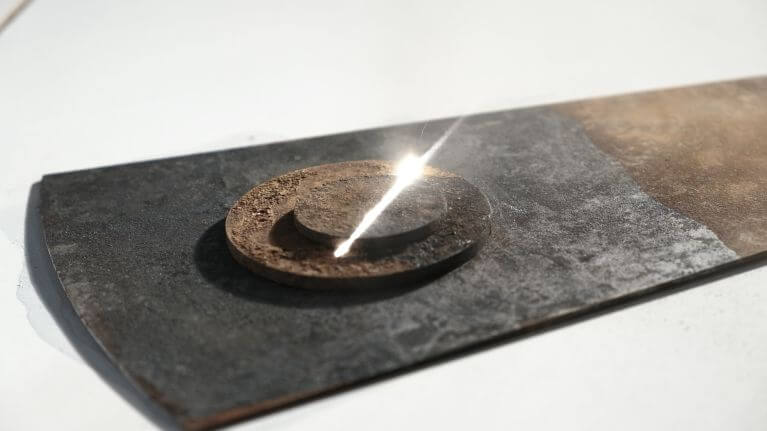

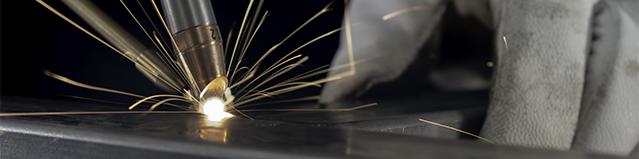

Advanced Technology: We use state-of-the-art laser welding equipment, ensuring millimetric precision and clean, consistent joints.

-

Expert Team: Our team of highly skilled technicians and welders enables us to successfully tackle complex projects.

-

Material Versatility: We work with a wide range of materials, from steels and aluminum to more specialized materials, adapting to the needs of each client.

-

Sustainability: Our welding techniques minimize material waste and optimize resources, contributing to sustainable and environmentally responsible projects.

Applications of Our Welding Expertise

Automotive: Welding of chassis, structural components, and exhaust systems.

Aerospace: Assembly of critical parts requiring precision and high resistance.

Construction: Metal structures, supports, and heavy machinery assemblies.

Electronics: High-precision metallic connections in technological devices.

Conclusion

At LC LASERS, we understand that welding quality is the cornerstone of a successful project. Our combination of technology, expertise, and commitment allows us to deliver solutions that ensure safety, durability, and efficiency. If you are looking for a reliable partner for your welding projects, contact us and discover how we can assist you!