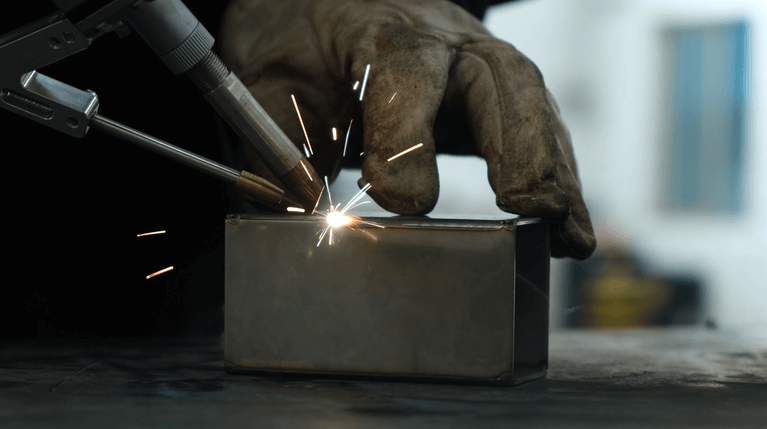

Laser cleaning of rust on metals

Summary:

LC-CLEAN allows us to remove rust and other contaminants from a metal surface. It is a non-abrasive process, which reduces the risk of damaging the surface or changing its original shape. Being a non-contact system, the laser can reach areas that are difficult to access, making it suitable for cleaning PIECES with complex geometries.

At LC Lasers, we offer a laser cleaning solution that exceeds the quality standards established in the market, allowing us to enhance the cleaning processes in industrial environments.

In the following article, we will discuss the benefits of lasers in the cleaning sector and some examples of applications.

Removing rust from metal surfaces

Using the laser, we can remove the oxide layer that forms on the metal surface due to the interaction of the metal with the oxygen present in the air or water. The laser beam heats the oxide, which causes it to evaporate into gases. At the same time, it causes the oxide to detach from the metal surface, leaving the substrate clean.

It seems impossible, but this process, which sounds very rigorous, can be achieved in a matter of seconds, thanks to the LC-CLEAN, a laser cleaning equipment capable of removing all types of dirt, without damaging the base surface.

In this case we have worked removing a layer of rust from a metal PIECE, but laser cleaning can also be applied to coatings, paints, grease and other types of deterioration.

Key benefits of the laser cleaning machine:

The laser cleaning machine has a number of advantages over traditional cleaning methods. The following are the key benefits of the LC-CLEAN.

High cleaning speed. It is a fast and efficient process. LC-CLEAN can effectively remove rust in a short time, allowing us to speed up production times and reduce downtime.

No chemicals or abrasives. Compared to alternative cleaning methods, the laser system does not require additional corrosive substances to remove rust. This makes it an environmentally friendly and safer option.

No damage to the base material. The laser cleaning equipment is fully configurable to achieve a high level of precision, removing only the rust without damaging the substrate. This is an important factor when cleaning delicate or high-value products.

Versatility. With the laser cleaning system, we can work a wide range of surfaces and materials, including stainless steel, galvanized steel, aluminum, among others. This makes it a versatile equipment that can be used in sectors such as industrial, food, automotive, etc.

Other laser cleaning applications:

As mentioned in the previous section, laser cleaning machines are versatile equipment that allows us to work with a wide range of materials ranging from stainless steel, galvanized steel, plastics, among others. They can extract resin, stains, dirt, coatings, paint, grease and oil. This feature makes LC-CLEAN a viable option in the industrial, automotive, naval, construction, food and other sectors.

Here are two videos that demonstrate the effectiveness of laser cleaning in other applications. You will be able to appreciate the speed at which it works and the quality of its results.