Laser cleaning for carbon steel molds

Summary:

The baking pans used in the food industry are composed of different metals and coatings designed to SUPPORT the baking of the product to be baked.

Although rust can contain bacteria that can cause illnesses such as tetanus, a small amount of rust or discoloration on a baking pan may not be harmful if it has been thoroughly cleaned and most of the rust and discoloration removed from the inside of the pan.

When iron rusts, rust forms on the outside of the metal. Rust can also form on other metals alloyed with iron, such as steel. LC introduces LC-CLEAN as an all-in-one cleaning solution that uses no contaminants and generates no waste, providing a complete solution.

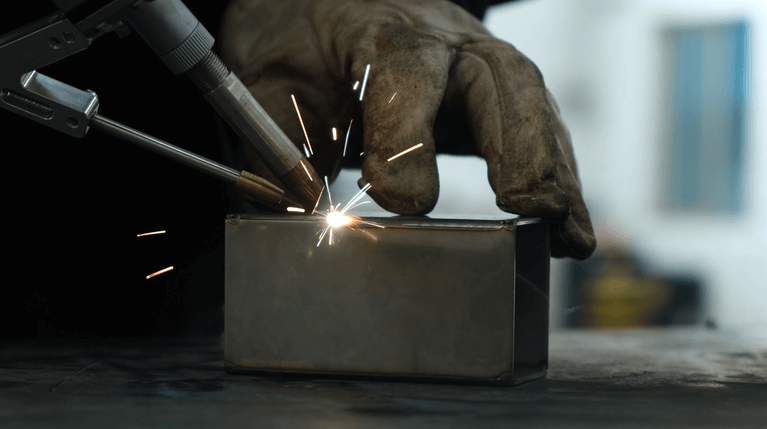

Laser cleaning of carbon steel molds

LC-CLEAN is a compact equipment with a maneuverable design that allows us to clean different materials at an incredible speed.

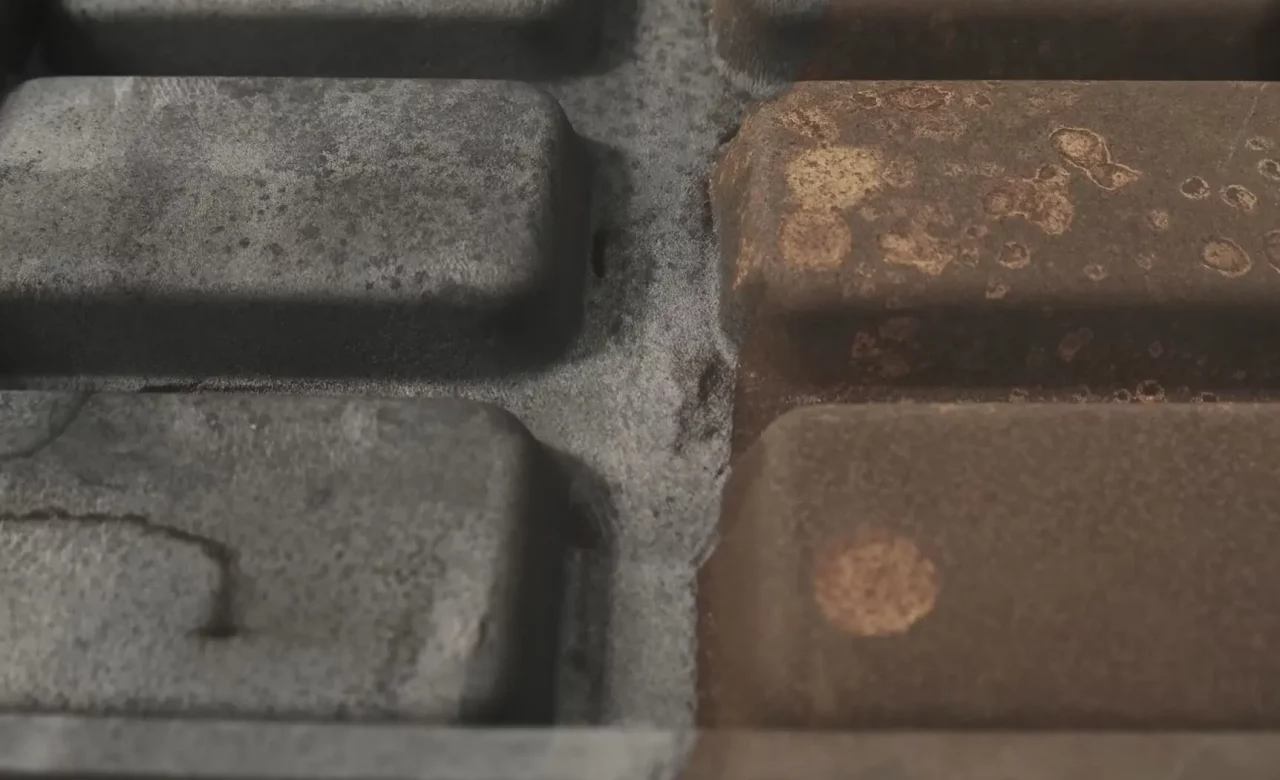

In the food industry, molds are often used to shape food preparations such as bread or some desserts. These molds are usually made of carbon steel to assist the baking of these food products. Carbon steel is a material that tends to get dirty or rusty.

These particles of rust or grease are very harmful to health, so they require proper cleaning to remove this dirt. In the case of grease, a thorough cleaning is sufficient. In the case of rust it is an even more complicated process because it may require different cleaning methods. This is where LC brings us laser cleaning, which is a contaminant and residue free solution.

In the same way, steel baking trays, molds and conveyor belts can be cleaned to remove dirt, grease and rust.

Laser cleaning of other metals

Laser cleaning can be used on different metals, including steel, aluminum, copper, titanium, nickel and metal alloys. Some metals are more sensitive to heat and may be damaged if subjected to high temperatures during laser cleaning.

In addition, the effectiveness of laser cleaning may also depend on the type of contaminants present on the surface of the metal. Some contaminants, such as rust, can be easily removed by laser cleaning, while other contaminants may require different cleaning techniques.

In general, laser cleaning is an effective and versatile cleaning technique for metals that can be used to remove a wide variety of surface contaminants. However, it is important to consider the specific properties of the metals and contaminants involved before using laser cleaning in a given cleaning process.

Advantages of laser cleaning of carbon steel

Laser cleaning is a technique that can provide several advantages over conventional cleaning when applied to carbon steel. Some of these advantages include:

- No damage to the steel surface: Laser cleaning does not damage the surface of carbon steel, as can occur with some chemical cleaning methods. The laser beam can be precisely controlled to remove only the layer of contamination from the surface of the steel, without affecting the internal structure of the material.

- No residue: Laser cleaning generates no residue, which can be a significant advantage over other cleaning methods, which can leave residue or generate hazardous chemicals.

- Reduces cleaning time and costs: Laser cleaning can be faster and more efficient than other cleaning methods. By using a laser beam, contaminants can be removed from the surface of carbon steel faster and with less manual effort, which can reduce cleaning time and costs.

- Increased accuracy: Laser cleaning is a highly precise technique and the amount of energy applied to the steel surface can be controlled. This allows only contaminants to be removed from the surface of the steel and preserves the structure and integrity of the material.